Well, the TSX needed new wheels....ISF is back (Page 64)

#1843

Thread Starter

Moderator

Regional Coordinator (Southeast)

Regional Coordinator (Southeast)

Joined: Dec 2003

Posts: 43,665

Likes: 3,908

From: Mooresville, NC

The failsafe is great but I read one problem. It is hard to incorporate the failsafe feature into factory ecu. The only real way I found from the LS forums is to have the failsafe trigger a fault at the IAT sensor and program the ecu when it sees the IAT sensor issue to put the car in limp mode.

I definitely love the idea of have a way to automatically prevent issues from happening for sure. I would also technically need two failsafes for most of what I have read so I can have one in each header reading each banks A/F ratio.

You can buy that custom faceplate for the bottom cubby from WeaponX for $70.

I definitely love the idea of have a way to automatically prevent issues from happening for sure. I would also technically need two failsafes for most of what I have read so I can have one in each header reading each banks A/F ratio.

You can buy that custom faceplate for the bottom cubby from WeaponX for $70.

#1846

Thread Starter

Moderator

Regional Coordinator (Southeast)

Regional Coordinator (Southeast)

Joined: Dec 2003

Posts: 43,665

Likes: 3,908

From: Mooresville, NC

Obviously you can't base everything on what you read on other people's setups and dyno numbers but from reading the thread with mods and dyno numbers I see people anywhere between 580 and all the way up to 660whp with similar mods. I don't know what you are considering to be crazy numbers though. I don't really want to lose my clock so maybe I will lose the cubby space instead.

#1848

Thread Starter

Moderator

Regional Coordinator (Southeast)

Regional Coordinator (Southeast)

Joined: Dec 2003

Posts: 43,665

Likes: 3,908

From: Mooresville, NC

So continuing to do reading about the LS platform and possible issues and things I can do to prevent them for a reliab DD with power. Apparently the LSA uses plastic lifters and plastic lifter trays. With higher power they apparently fail. Should I be adding T-Bar lifters to my build as well Majofo, Kam, J? Again going for the most reliability possible for the longest amount of miles.

#1849

New cam is definitely deserved of new trays. I'm surprised that's not part of the package. Lifters are definitely not plastic. Tie bars might be overkill unless that cam is more on the aggressive side. If she's going to spin the same revs at a mild ramp, plastic tray is fine. Use new ones though. You definitely want to go with a tried and true setup if you opt for lifters with cross bars. That could be even worse.

#1853

Thread Starter

Moderator

Regional Coordinator (Southeast)

Regional Coordinator (Southeast)

Joined: Dec 2003

Posts: 43,665

Likes: 3,908

From: Mooresville, NC

New cam is definitely deserved of new trays. I'm surprised that's not part of the package. Lifters are definitely not plastic. Tie bars might be overkill unless that cam is more on the aggressive side. If she's going to spin the same revs at a mild ramp, plastic tray is fine. Use new ones though. You definitely want to go with a tried and true setup if you opt for lifters with cross bars. That could be even worse.

You think lifters with cross bars could actually be worse? I like the idea that they complete remove the possibility of having a lifter sping and destroy the cam and then put metal through the engine. When I emailed the shop they said the stock LSA ones were what they planned on using but if I wanted they have also used LS7 and Comp Cam Short Travel lifters as well and we could go that route.

Again I know I keep saying this and maybe this goal has me over thinking things but I want to make this extra reliable. I want to be able to change my oil every 3-5k miles and drive this like a stock V that has been modded. No extra worries or anything. Maybe that isn't 100% possible but I want to get it close to that.

#1854

i would go Johnson 2110 and not look back... i wouldn't risk your $7k build on the $300 difference you will pay on the lifters...

#1855

Again I know I keep saying this and maybe this goal has me over thinking things but I want to make this extra reliable. I want to be able to change my oil every 3-5k miles and drive this like a stock V that has been modded. No extra worries or anything. Maybe that isn't 100% possible but I want to get it close to that.

i have no doubts that the shop will build your car reliable since that is your first requirement... but you will now have to balance the other two...

#1856

Thread Starter

Moderator

Regional Coordinator (Southeast)

Regional Coordinator (Southeast)

Joined: Dec 2003

Posts: 43,665

Likes: 3,908

From: Mooresville, NC

if GM didn't already have issues with their lifters on their stock cams, i'd tell you to go OEM LS7 lifters since that motor revs higher than ours and i don't think you plan on raising your redline... but look at how many C6Z have valve issues... i think Rick's Z already had the head redone... my best bud is waiting to send his car to Katech in October to have his head redone with only 15k miles on it...

i would go Johnson 2110 and not look back... i wouldn't risk your $7k build on the $300 difference you will pay on the lifters...

i would go Johnson 2110 and not look back... i wouldn't risk your $7k build on the $300 difference you will pay on the lifters...

I am hoping this build will net me around 600whp. That would leave me just a little work for later for my total goal of the car of around 650whp and being super reliable daily.

#1857

600 on pump gas is going to be a super quick grocery getter that will drive like stock... you can easily gain that other 50 you are looking for by going E85... i wouldn't sweat it...

i think my ultimate goal is to just get the 556hp (advertised crank hp) to the wheels... i'm trying to keep it reasonable since i still drive the car during the winter and with the snow up here, that would be it for me... it would drive like stock and not skip a beat... until i move to a warmer climate where i could keep Summer tires on it all year round and put the power down, i won't aim for the sky just yet...

you have the TSX to really go crazy when you need to, just like i plan on doing with the MR2...

i think my ultimate goal is to just get the 556hp (advertised crank hp) to the wheels... i'm trying to keep it reasonable since i still drive the car during the winter and with the snow up here, that would be it for me... it would drive like stock and not skip a beat... until i move to a warmer climate where i could keep Summer tires on it all year round and put the power down, i won't aim for the sky just yet...

you have the TSX to really go crazy when you need to, just like i plan on doing with the MR2...

#1863

[ utag]Mr. Maker[/utag ]

#1864

Thread Starter

Moderator

Regional Coordinator (Southeast)

Regional Coordinator (Southeast)

Joined: Dec 2003

Posts: 43,665

Likes: 3,908

From: Mooresville, NC

600 on pump gas is going to be a super quick grocery getter that will drive like stock... you can easily gain that other 50 you are looking for by going E85... i wouldn't sweat it...

i think my ultimate goal is to just get the 556hp (advertised crank hp) to the wheels... i'm trying to keep it reasonable since i still drive the car during the winter and with the snow up here, that would be it for me... it would drive like stock and not skip a beat... until i move to a warmer climate where i could keep Summer tires on it all year round and put the power down, i won't aim for the sky just yet...

you have the TSX to really go crazy when you need to, just like i plan on doing with the MR2...

i think my ultimate goal is to just get the 556hp (advertised crank hp) to the wheels... i'm trying to keep it reasonable since i still drive the car during the winter and with the snow up here, that would be it for me... it would drive like stock and not skip a beat... until i move to a warmer climate where i could keep Summer tires on it all year round and put the power down, i won't aim for the sky just yet...

you have the TSX to really go crazy when you need to, just like i plan on doing with the MR2...

You know I have still not figured out how to use that tag system either. I feel like a newb.

No nitrous for me. Just don't want the added risk. Even with doing forged pistons it doesn't really interest me.

#1866

Thread Starter

Moderator

Regional Coordinator (Southeast)

Regional Coordinator (Southeast)

Joined: Dec 2003

Posts: 43,665

Likes: 3,908

From: Mooresville, NC

This shop prefers comp cam lifters or LS7 and just told me he is running LS7 lifters in his personal at 900hp. But said he has 4 sets of johnson lifters in customer cars and had 2 sets fail on the dyno. Also told my Mamo LS7 ported TB is a waste of money and I should just go straight to a 102mm with a 4.5in intake if I want to make more power. Really out of my knowledge area on this motor and rushing to try and learn stuff as I go with this build is not giving me the confidence I was hoping on being able to choose parts.

#1870

This shop prefers comp cam lifters or LS7 and just told me he is running LS7 lifters in his personal at 900hp. But said he has 4 sets of johnson lifters in customer cars and had 2 sets fail on the dyno. Also told my Mamo LS7 ported TB is a waste of money and I should just go straight to a 102mm with a 4.5in intake if I want to make more power. Really out of my knowledge area on this motor and rushing to try and learn stuff as I go with this build is not giving me the confidence I was hoping on being able to choose parts.

as for the TB, the stock 87mm can go 700hp and i think the 90mm is rated to like 800 whp... of course bigger is always better but whats the point of a 102mm tb if your s/c snout necks you down to 90mm anyway? are you planning to have the snout and blower port matched to 102mm as well??? i personally would rather keep the flow consistent and smooth from the intake all the way into the blower... it's easy to want to throw big TB, big intake since bigger is better... but even for your 700whp, if you stuck with the mamo 87mm and Airaid, you still would be fine...

and if i am not mistaken, for a 102, you going to need an adapter plate for clearance...

#1871

Thread Starter

Moderator

Regional Coordinator (Southeast)

Regional Coordinator (Southeast)

Joined: Dec 2003

Posts: 43,665

Likes: 3,908

From: Mooresville, NC

Yeah I really have no interest in the NW102. Sure it looks really nice and all but I have seen lots of issues with reliability and idle and what not with it. The LS7 seems tried and true and I already had ordered it so that is what I am going with. I am not having the blower or snout ported at this time. So I won't fully even be taking advantage of the 90mm really but oh well I guess. There are guys on ctsv saying why are you not porting the heads while you have them off. Well I don't have another 2k laying around so I can do it right. But yeah the LS7 and 700whp is the max I would ever think of going. I am not out chasing that little extra 1,3, or 7hp it might gain me with my current build. Who knows if this one nets me 600whp I may never touch it again.

On the valves this might be the one time I just pick a part and say I want this in my build cause I just have yet to see anyone mention an issue with the 2110 if you are keeping the engine at or below 7000rpm. Without doing heads I don't really think there are any majore gains to be had going above 7000rpm anyways from my brief reading of things. At least not major gains anyways.

On the valves this might be the one time I just pick a part and say I want this in my build cause I just have yet to see anyone mention an issue with the 2110 if you are keeping the engine at or below 7000rpm. Without doing heads I don't really think there are any majore gains to be had going above 7000rpm anyways from my brief reading of things. At least not major gains anyways.

#1872

There are guys on ctsv saying why are you not porting the heads while you have them off. Well I don't have another 2k laying around so I can do it right. But yeah the LS7 and 700whp is the max I would ever think of going. I am not out chasing that little extra 1,3, or 7hp it might gain me with my current build. Who knows if this one nets me 600whp I may never touch it again.

On the valves this might be the one time I just pick a part and say I want this in my build cause I just have yet to see anyone mention an issue with the 2110 if you are keeping the engine at or below 7000rpm. Without doing heads I don't really think there are any majore gains to be had going above 7000rpm anyways from my brief reading of things. At least not major gains anyways.

On the valves this might be the one time I just pick a part and say I want this in my build cause I just have yet to see anyone mention an issue with the 2110 if you are keeping the engine at or below 7000rpm. Without doing heads I don't really think there are any majore gains to be had going above 7000rpm anyways from my brief reading of things. At least not major gains anyways.

#1873

Thread Starter

Moderator

Regional Coordinator (Southeast)

Regional Coordinator (Southeast)

Joined: Dec 2003

Posts: 43,665

Likes: 3,908

From: Mooresville, NC

i'm sure you already know this, but it is really easy to go overboard when you do this kind of build... since everything is open, the small little upgrades here and there can start to add up... oh you have the heads off anyway why not just port them... oh you are upgrading the tb, why not port that too... the block is opened so lets use ARP fasteners everywhere... it can easily rack in thousands onto your bill... i love it when these guys swing their d!cks chasing numbers... you can overbuild certain things for insurance as long as you use your budget wisely...

Just got off the phone with the guy at the shop and they very much like the GM LS7 and Comp Cam T bar lifters but the internet has me scared of them. He said if it was his car he would do new trays and GM LS7 if with my setup right now. If I wanted to do an upgrade then he suggests to not do trays anymore and then do a T-bar style and says he has had great luck with the Comp Cam Tbar that everything I find on the internet says to stay away from. That being said he would never warranty anything he doesn't design himself. He will stand behind 100% of the work they do but not parts manufactured by someone else. I fully expected and have no issue with that answer. I would imagine every engine builder would say that.

Not being sold on either one of those and everyone having great luck with the Johnson lifters I think for this I might make my own decision and go against the shops advice. I just need to decide between 2110 with trays or 2116 with Tbars now. The 2110 has more travel compared to the 2116. At this point I am getting into things I don't fully understand yet. I get that with more travel you don't need to worry about matching pushrod lengths. I told him I don't want to hold up the build at all but that I need some more time to figure out what I want to go with. He said if I make a decision by early next week it won't delay anything.

Some of this information I am getting is coming from these threads.

Johnson 2110 lifter preload

So lets talk about our Lifters and recent lifter failure with new cams

I also got a little more information on the cam but nothing really useful probably. He described the custom grind cam he designs to make great power while still having great driveability. He said he has a second came design for the LSA that he created a little while after the first one that will sacrafice some driveability for a little more power but for what I want he doesn't recommend it at all.

#1874

Thread Starter

Moderator

Regional Coordinator (Southeast)

Regional Coordinator (Southeast)

Joined: Dec 2003

Posts: 43,665

Likes: 3,908

From: Mooresville, NC

Here is a car they just completed I saw on their site. I would imagine it would have the more aggressive of their two cams. It is a bit more than I want to have on mine but it does still sound good.

http://www.jhrperformance.com/posts/custom-grind-jhr/

http://www.jhrperformance.com/posts/custom-grind-jhr/

#1875

Thread Starter

Moderator

Regional Coordinator (Southeast)

Regional Coordinator (Southeast)

Joined: Dec 2003

Posts: 43,665

Likes: 3,908

From: Mooresville, NC

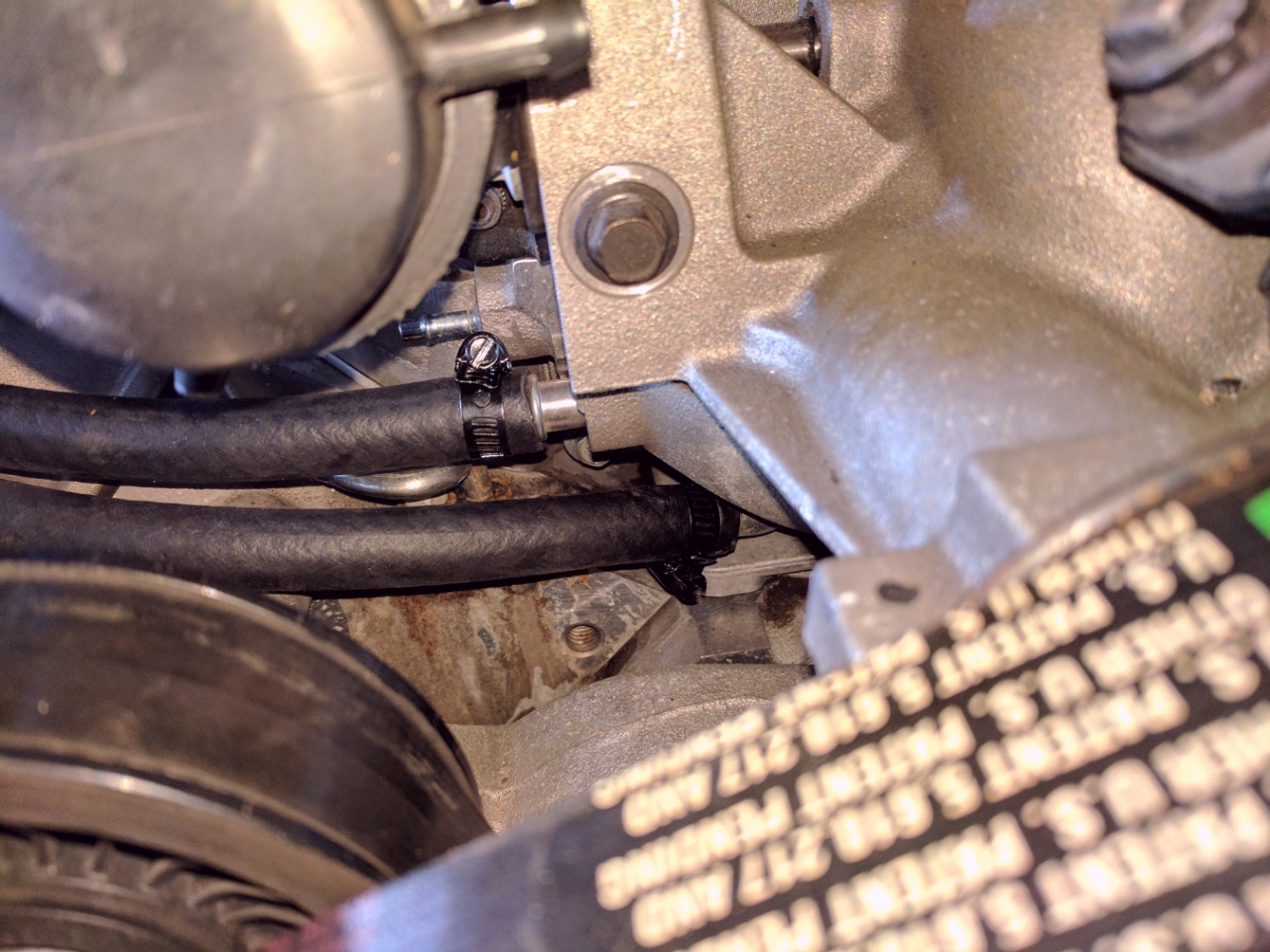

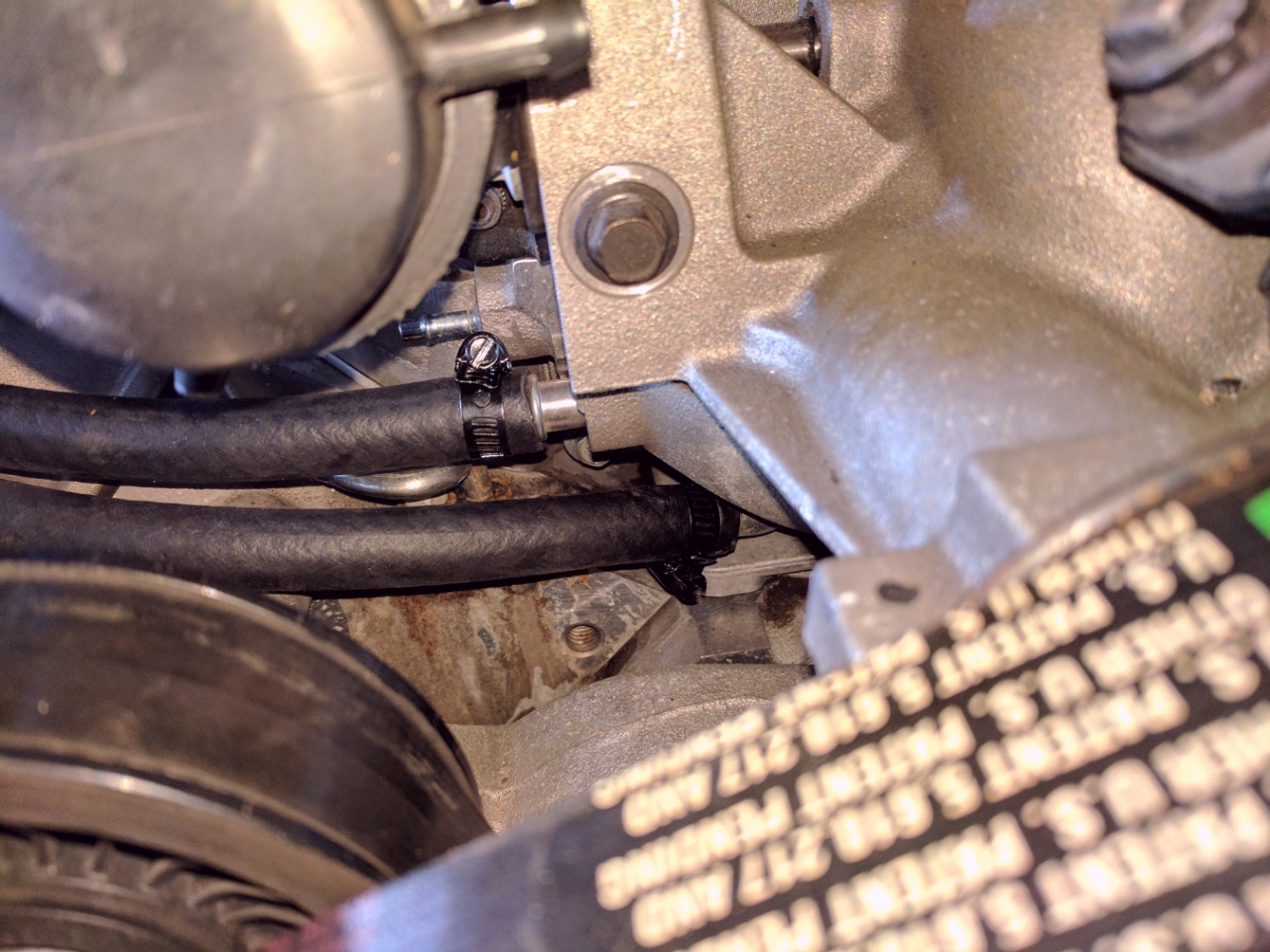

So this is a little late in the order of things but here is the catch can install and green filter I did a few weeks back right before the car went to the shop.

This is the new Dual SMC Catch can that you can only get through WeaponX. It was made exclusively for them to sell to the CTS-V community.

I didn't want shiny silver hose clamps on the install. I wanted something a bit more stealth for the catch can. I tracked down some black coated hose clamps to use. They only come in a 10pack though which turned out to be just enough if I didn't use them for the remote drain hose.

Joined the two drains together as one since I am really just running the dual cans in parallel on the valley/snout connection. These drain locations though do end up causing some install issues later on. I don't think it is a huge issue though.

To remote the valley/snout link you can make it easier by removing the vacuum/pressure sensor from the bypass valve of the blower. It just gives you a few extra inches to work with. Just make sure you remember to plug the connection in tightly when you put it back on.

With it out of the way I also remove the seconday hose that is connected to the bypass valve

With this gone and using a long screwdriver to release the clip it makes removing this hose very easy. Mine had a ton of oil in it but it turns out there was more than one reason for that.

One of my best investments ever is this Mac Tool screwdriver set. Flexible screwdriver was so handy in installing the hose clamps on these two lines.

Test fitting the can location I figured out I needed to change the way the hose the linked can A to can B. I originally had it going under the outlet hose and that really messed up running the lines cleanly. That hose goes on those barbed connections on the can so tight though I had to actually cut it off. This gave me a chance to also shorten the loop by 1inch.

Some nice stainless steel allen screw hardware I picked up to mount the cans with

Now here is the issue I mentioned earlier with the drains. Using the thick fuel line tubing I used for this makes the cans not sit perfectly straight up and down. I don't think from a functionaliy stand point this will ever be an issue. It could become an issue for getting everything drained out of the cans though.

Drain hose came with some heat tubing for around the cats but I think really I need some more for where it passes by the manifold as well. I tied it as far away as I could with a zip tie for the time being.

Here is the remote drain kit I purchased to use with my setup. I like the fact it will allow me to easily drain the system every oil change or even more regularly with the fact it is so easy to access.

Here is how I ran the lines. Up allong the side of the engine and then arround the back. I figured it made the connetions to the can easier than having bends right in front of the cans if I cam around the other side. Plus it kept from having to go in front of the blower too.

Big green filter is really big

She barely fits in there.

This is the new Dual SMC Catch can that you can only get through WeaponX. It was made exclusively for them to sell to the CTS-V community.

I didn't want shiny silver hose clamps on the install. I wanted something a bit more stealth for the catch can. I tracked down some black coated hose clamps to use. They only come in a 10pack though which turned out to be just enough if I didn't use them for the remote drain hose.

Joined the two drains together as one since I am really just running the dual cans in parallel on the valley/snout connection. These drain locations though do end up causing some install issues later on. I don't think it is a huge issue though.

To remote the valley/snout link you can make it easier by removing the vacuum/pressure sensor from the bypass valve of the blower. It just gives you a few extra inches to work with. Just make sure you remember to plug the connection in tightly when you put it back on.

With it out of the way I also remove the seconday hose that is connected to the bypass valve

With this gone and using a long screwdriver to release the clip it makes removing this hose very easy. Mine had a ton of oil in it but it turns out there was more than one reason for that.

One of my best investments ever is this Mac Tool screwdriver set. Flexible screwdriver was so handy in installing the hose clamps on these two lines.

Test fitting the can location I figured out I needed to change the way the hose the linked can A to can B. I originally had it going under the outlet hose and that really messed up running the lines cleanly. That hose goes on those barbed connections on the can so tight though I had to actually cut it off. This gave me a chance to also shorten the loop by 1inch.

Some nice stainless steel allen screw hardware I picked up to mount the cans with

Now here is the issue I mentioned earlier with the drains. Using the thick fuel line tubing I used for this makes the cans not sit perfectly straight up and down. I don't think from a functionaliy stand point this will ever be an issue. It could become an issue for getting everything drained out of the cans though.

Drain hose came with some heat tubing for around the cats but I think really I need some more for where it passes by the manifold as well. I tied it as far away as I could with a zip tie for the time being.

Here is the remote drain kit I purchased to use with my setup. I like the fact it will allow me to easily drain the system every oil change or even more regularly with the fact it is so easy to access.

Here is how I ran the lines. Up allong the side of the engine and then arround the back. I figured it made the connetions to the can easier than having bends right in front of the cans if I cam around the other side. Plus it kept from having to go in front of the blower too.

Big green filter is really big

She barely fits in there.

Last edited by CCColtsicehockey; 02-16-2017 at 08:35 AM.

The following users liked this post:

00TL-P3.2 (02-16-2017)

The following users liked this post:

CCColtsicehockey (02-16-2017)

The following users liked this post:

CCColtsicehockey (02-16-2017)

#1878

Thread Starter

Moderator

Regional Coordinator (Southeast)

Regional Coordinator (Southeast)

Joined: Dec 2003

Posts: 43,665

Likes: 3,908

From: Mooresville, NC

New Mamo LS7 TB and also the reinforced brick arrived this past week. I just took them up to the shop today. I found out while I was there that there was no damage to the block. They will just do a clean hone and be able to use stock size drop in forged pistons which should only raise the compression a little bit. Still on schedule as of now to have it back the end of next week or early the following week.

The following users liked this post:

CCColtsicehockey (02-28-2017)

The following users liked this post:

CCColtsicehockey (02-28-2017)