RonJon Wheels Exclusive: The Birth of an LPC Aluminum Wheel (Inspyre Type II)

#1

RonJon Wheels Exclusive: The Birth of an LPC Aluminum Wheel (Inspyre Type II)

Purpose of this thread

This is a project thread to show how a Low Pressure Cast Aluminum wheel is created. Just thought it would be a great way to show the enthusiast what goes into product design, development, testing and production. With something as simple as a wheel, it's easy to take for granted the hard work that goes into development. Enjoy!

But first...

Quick history on the RonJon Sport Design co.

You all probably know me by now, My name is Rondy, company founder over here at RonJon Sport Design. My company was born on the Acurazine boards before it was even called Acurazine. Back when Adam and Rob ran the show. I've been a lurker since 2000 and an active member since 2001. Since then we have been featured in the most popular magazines in the world. Also, we have earned the title as the only independent wheel and styling company dedicated to Honda and Acura vehicles in the world. (Mugen is supported by Honda Corp, we are not).

A few publications we have been featured in...

Here's a quick article in Honda Tuning on how the company was started:

http://ronjonwheels.com/ronjonimages.../press/ht6.jpg

The Original Inspyre from 2004-2009

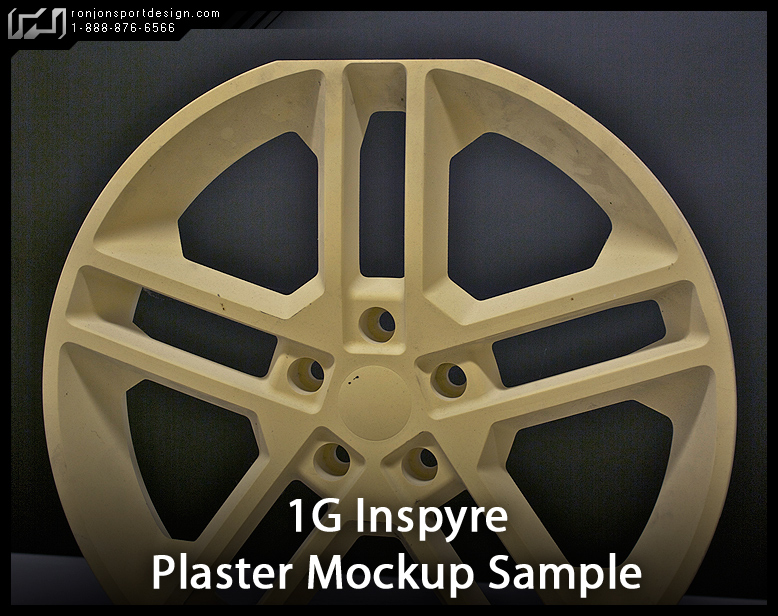

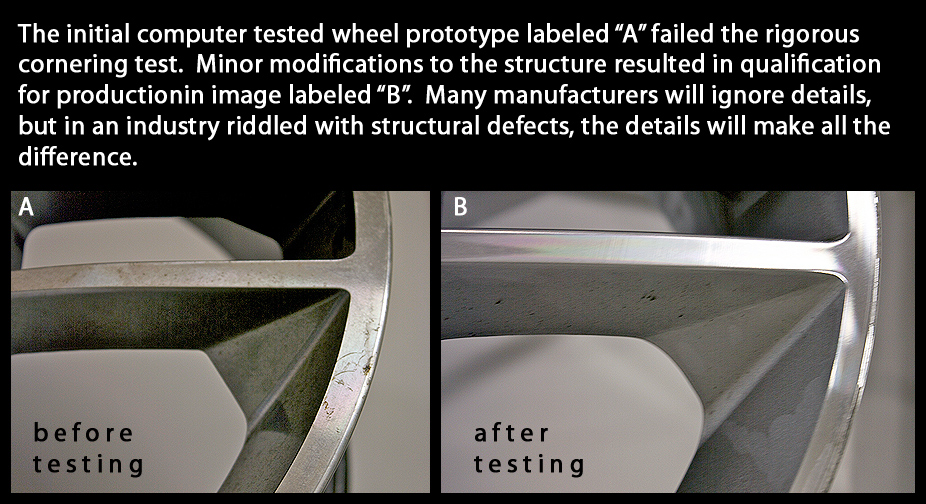

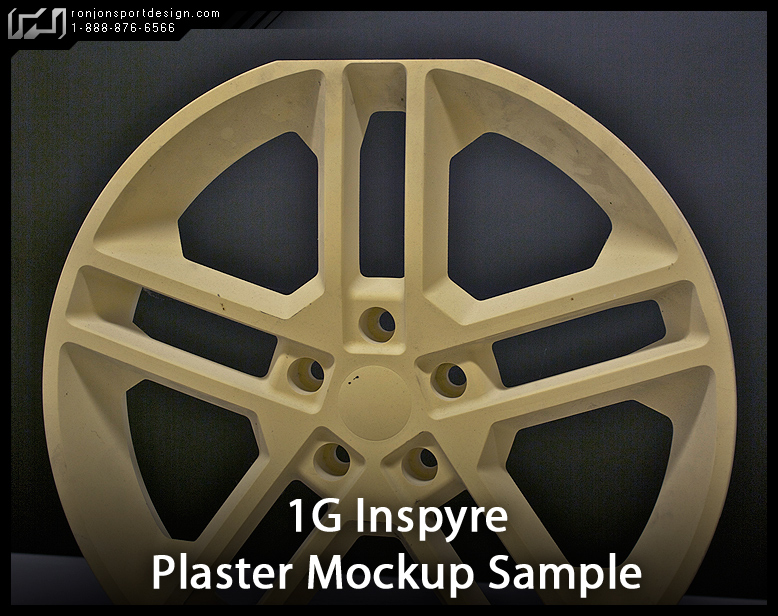

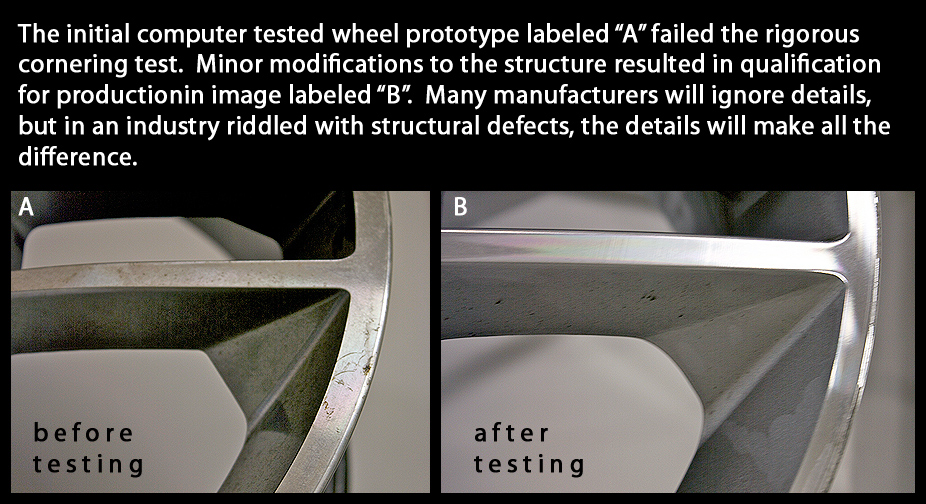

First we will start with the design in digital sketch form from the 1st Gen Inspyre (codename RJ3). This wheel was very popular and stood the test of time since it was designed in studio and without regard to trends of that time that fade in 1-2 years. First was the design, then was the 3D render for advertising, followed by the plaster mockup for approval purposes. Finally the production version which was sold to the public. In between the plaster mockup and the production piece, minor adjustments to the structure were made to ensure that the $20k+ mold would not reap any defects:

Sketch rendered in Photohop:

The 3D render (without engineering):

The plaster mockup prior to testing:

One example of the adjustments needed to pass structural testing.

Final production version:

Shown on vehicles from 2004:

Tomorrow we will start with the beginning stages of the 2nd Gen Inspyre type II, down to the packaging and centercap design. Stay tuned!

This is a project thread to show how a Low Pressure Cast Aluminum wheel is created. Just thought it would be a great way to show the enthusiast what goes into product design, development, testing and production. With something as simple as a wheel, it's easy to take for granted the hard work that goes into development. Enjoy!

But first...

Quick history on the RonJon Sport Design co.

You all probably know me by now, My name is Rondy, company founder over here at RonJon Sport Design. My company was born on the Acurazine boards before it was even called Acurazine. Back when Adam and Rob ran the show. I've been a lurker since 2000 and an active member since 2001. Since then we have been featured in the most popular magazines in the world. Also, we have earned the title as the only independent wheel and styling company dedicated to Honda and Acura vehicles in the world. (Mugen is supported by Honda Corp, we are not).

A few publications we have been featured in...

Here's a quick article in Honda Tuning on how the company was started:

http://ronjonwheels.com/ronjonimages.../press/ht6.jpg

The Original Inspyre from 2004-2009

First we will start with the design in digital sketch form from the 1st Gen Inspyre (codename RJ3). This wheel was very popular and stood the test of time since it was designed in studio and without regard to trends of that time that fade in 1-2 years. First was the design, then was the 3D render for advertising, followed by the plaster mockup for approval purposes. Finally the production version which was sold to the public. In between the plaster mockup and the production piece, minor adjustments to the structure were made to ensure that the $20k+ mold would not reap any defects:

Sketch rendered in Photohop:

The 3D render (without engineering):

The plaster mockup prior to testing:

One example of the adjustments needed to pass structural testing.

Final production version:

Shown on vehicles from 2004:

Tomorrow we will start with the beginning stages of the 2nd Gen Inspyre type II, down to the packaging and centercap design. Stay tuned!

The following users liked this post:

mattg (08-29-2013)

#2

In the Mid-South meow

iTrader: (2)

Thanks for the write up Ron! As a product designer (more graphic than structural) it's awesome to see what goes into making it a real product starting from a simple sketch/rendering. Very cool. Can't wait to see Type II!

#6

Inspyre Type II development

In all my years (12+) working with half a dozen or so well known wheel companies in the industry, I have watched them try to come up with the next big thing. First it was the spinners. Then it was the 30" wheel. Then it was the clear face wheel. Then it was the next trend, and the next. Now it has just passed as the concave wheel profile. These wheel companies were trying so hard to anticipate the next trend to get a headstart and cash out. I always looked at it as what would I want, not what would the customer want. So I asked myself, as a car enthusiast, what would I do if engineering and money were not an issue. I always wanted to change my style of wheels without buying a new set of wheels every 3 months because the cost was too high. And I'm sure you will all agree that it seems to be a pattern among us, the constantly changing sets of wheels. It's almost like a complex or disfunction among car enthusiasts. A solution to this need to change style without going broke could be solved by changing the style, without the need for a whole new set of wheels. Inserts without looking cheezy with rivets everywhere. This has been done already I thought. But the key detail would be to have hidden hardware with a look that is natural, not like melted wax with screws in it. This is how I presented it to the factory...

Step One: Overall design created

Inspyre Type II development first step is to submit the original wheel as a sample, and have the factory engineers reverse engineer the wheel. Meaning, they will use the actual wheel to design the new version. I gave them a list of instructions, like remove the triangle supports in the corners of the spokes per customer opinions. Also, we planned to make the centercap a pentagon shape, and finally, we made the lip and face separated by a thin groove, for custom finishing purposes. If a customer wants to have a black face with machined lip.

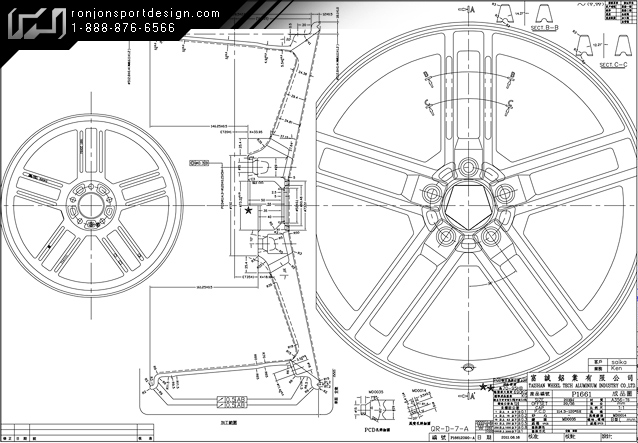

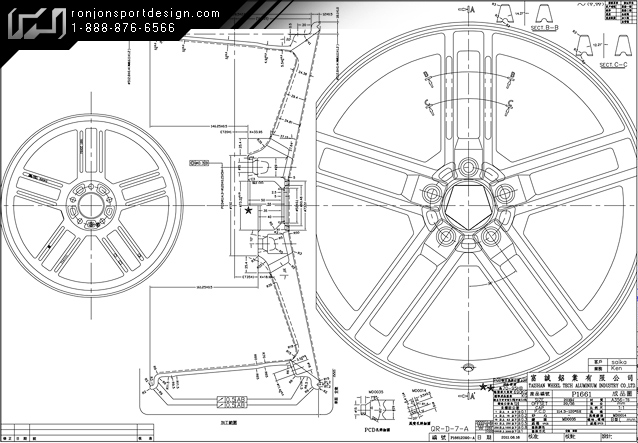

First they sent me the 2D CAD drawing so I can check caliper clearance, profile, design and structural details.

Step Two: Design is fine tuned alongside the factory engineers approval

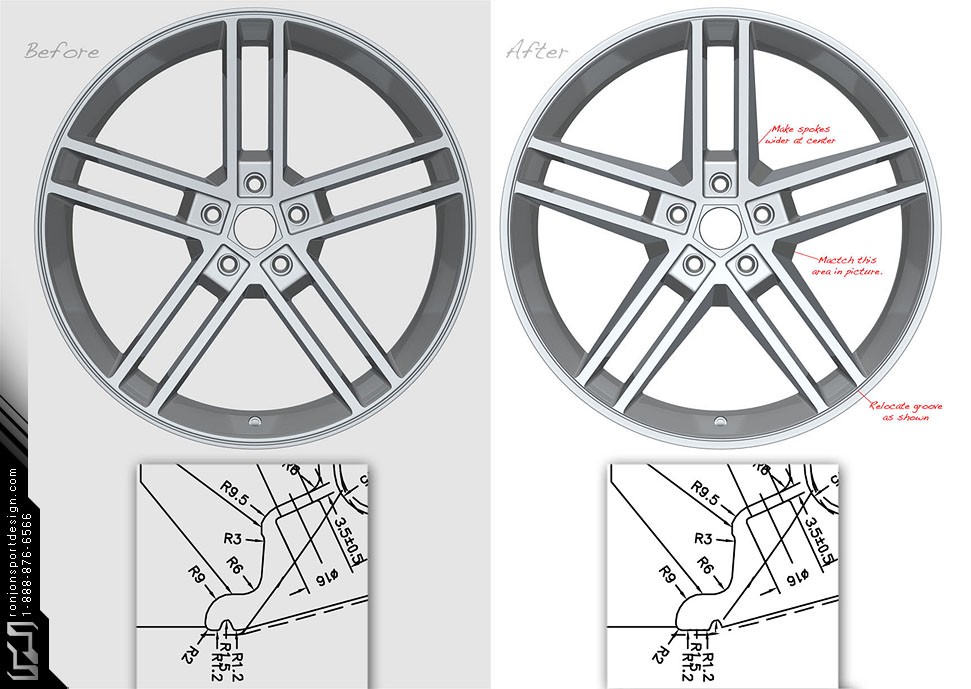

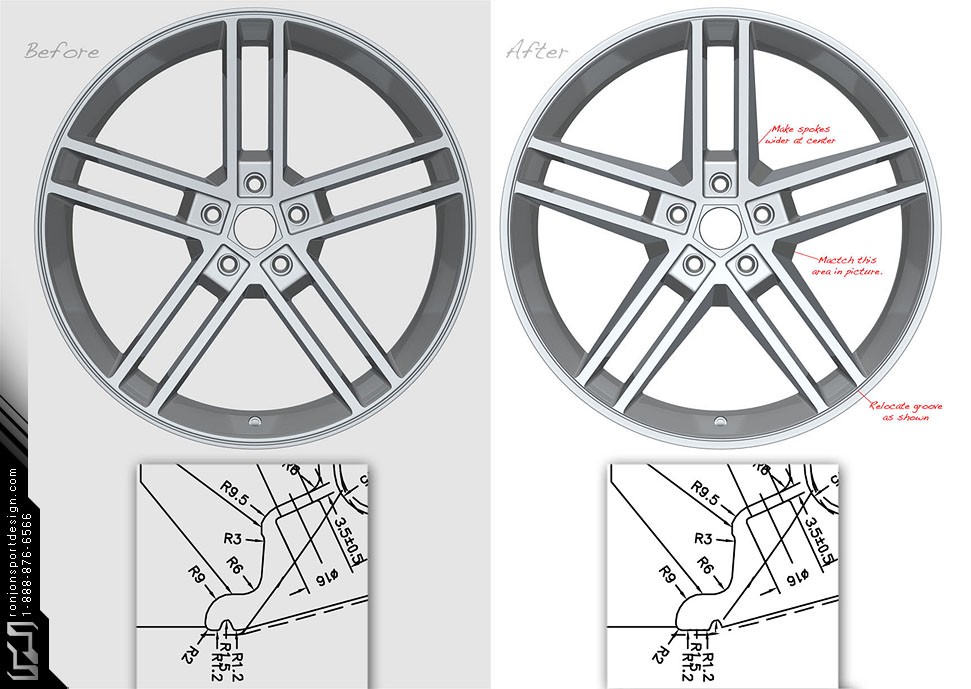

Next, this is what I got back from the factory engineers. Decent starting point, but not exactly what I envisioned compared to the 2D. So I marked up their CAD 3D image to better explain the needed adjustments as shown:

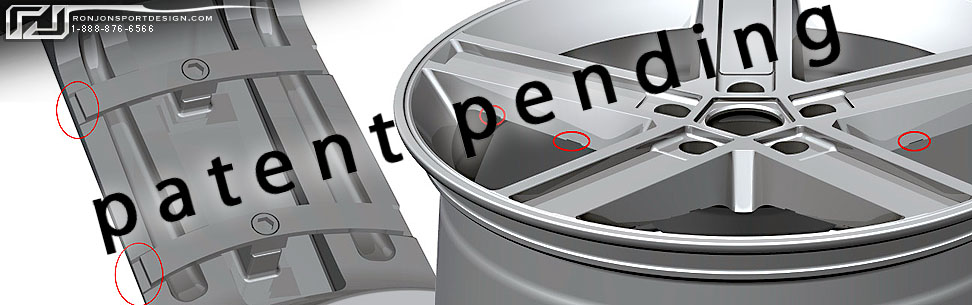

Step Three: Unique engineering features submitted

I also presented a challenge to the factory. To engineer a set of removable inserts that have hidden hardware. This is an industry first. My submission was pretty crude, with holes behind the spokes to mount the screws. But the factory suggested clamps, because the holes could compromise the strength of the wheel structure. This in of itself was a project. And not only did it have to look good, but it also had to pass the high speed test to make sure it doesn't become a weapon while driving at high speeds. More on this later.

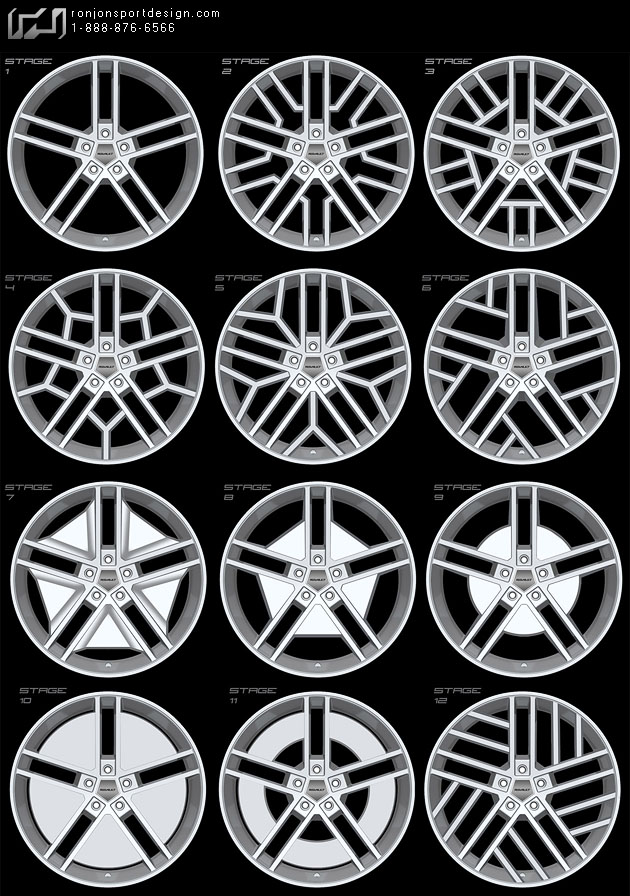

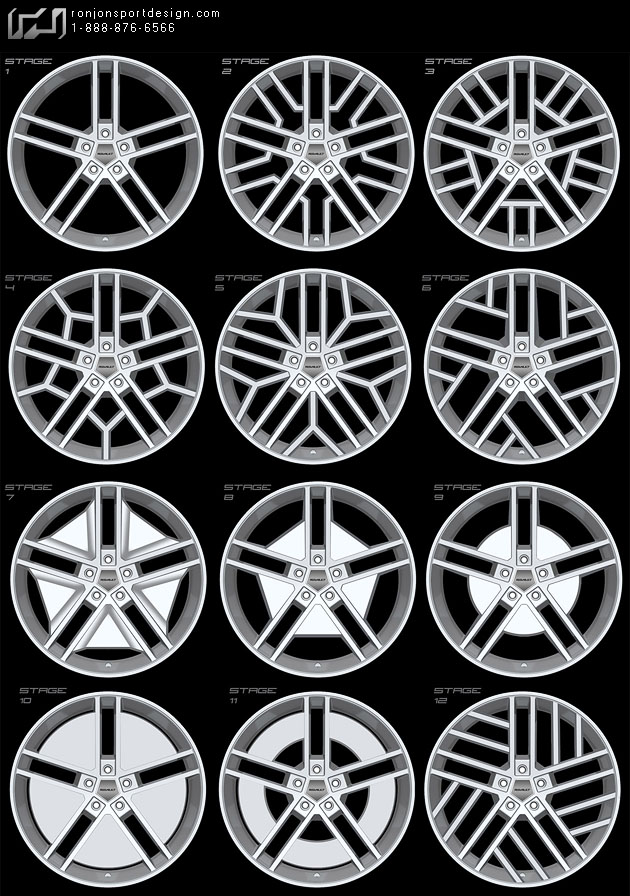

My plans were to make a sort of skeleton wheel that will be setup for future upgrades. Halfway through, I found out that the proposed insert designs might not all make it. But 3 major ones would be good enough given the new clamp system. These are the designs I submitted as a way to illustrate the potential of my idea.

In all my years (12+) working with half a dozen or so well known wheel companies in the industry, I have watched them try to come up with the next big thing. First it was the spinners. Then it was the 30" wheel. Then it was the clear face wheel. Then it was the next trend, and the next. Now it has just passed as the concave wheel profile. These wheel companies were trying so hard to anticipate the next trend to get a headstart and cash out. I always looked at it as what would I want, not what would the customer want. So I asked myself, as a car enthusiast, what would I do if engineering and money were not an issue. I always wanted to change my style of wheels without buying a new set of wheels every 3 months because the cost was too high. And I'm sure you will all agree that it seems to be a pattern among us, the constantly changing sets of wheels. It's almost like a complex or disfunction among car enthusiasts. A solution to this need to change style without going broke could be solved by changing the style, without the need for a whole new set of wheels. Inserts without looking cheezy with rivets everywhere. This has been done already I thought. But the key detail would be to have hidden hardware with a look that is natural, not like melted wax with screws in it. This is how I presented it to the factory...

Step One: Overall design created

Inspyre Type II development first step is to submit the original wheel as a sample, and have the factory engineers reverse engineer the wheel. Meaning, they will use the actual wheel to design the new version. I gave them a list of instructions, like remove the triangle supports in the corners of the spokes per customer opinions. Also, we planned to make the centercap a pentagon shape, and finally, we made the lip and face separated by a thin groove, for custom finishing purposes. If a customer wants to have a black face with machined lip.

First they sent me the 2D CAD drawing so I can check caliper clearance, profile, design and structural details.

Step Two: Design is fine tuned alongside the factory engineers approval

Next, this is what I got back from the factory engineers. Decent starting point, but not exactly what I envisioned compared to the 2D. So I marked up their CAD 3D image to better explain the needed adjustments as shown:

Step Three: Unique engineering features submitted

I also presented a challenge to the factory. To engineer a set of removable inserts that have hidden hardware. This is an industry first. My submission was pretty crude, with holes behind the spokes to mount the screws. But the factory suggested clamps, because the holes could compromise the strength of the wheel structure. This in of itself was a project. And not only did it have to look good, but it also had to pass the high speed test to make sure it doesn't become a weapon while driving at high speeds. More on this later.

My plans were to make a sort of skeleton wheel that will be setup for future upgrades. Halfway through, I found out that the proposed insert designs might not all make it. But 3 major ones would be good enough given the new clamp system. These are the designs I submitted as a way to illustrate the potential of my idea.

Trending Topics

#8

Senior Moderator

Another OG AZ/A-TL.com member! You are still the man.

I am really glad to see that your business is still doing so well and is so well published. I remember the beginning.

I remember my RJ wheels well from my 2G TL days.

BTW, how about some wheels for the RLX? It sorely needs....something in the wheel department.

I am really glad to see that your business is still doing so well and is so well published. I remember the beginning.

I remember my RJ wheels well from my 2G TL days.

BTW, how about some wheels for the RLX? It sorely needs....something in the wheel department.

#9

Team Owner

iTrader: (2)

Join Date: Jan 2008

Location: Kansas City, MO (Overland Park, KS)

Posts: 36,545

Received 6,470 Likes

on

5,162 Posts

Rondy-I love the new design. Inspyres have always been a favorite of mine. It just goes to show that you can improve on perfection!

#10

#11

Senior Moderator

Very Very cool. Thank you for sharing.

#13

Senior Moderator

#15

Senior Moderator

The Inspyre's were one of my favorite wheels for the RL. RJ needs more 5x120 options.

Last edited by oo7spy; 08-16-2013 at 01:50 PM.

#18

(Apologies for not replying to posts, I appreciate the fellowship, I'll keep you guys updated on my well being when I get the the end. Thanks my good freinds at AZ!)

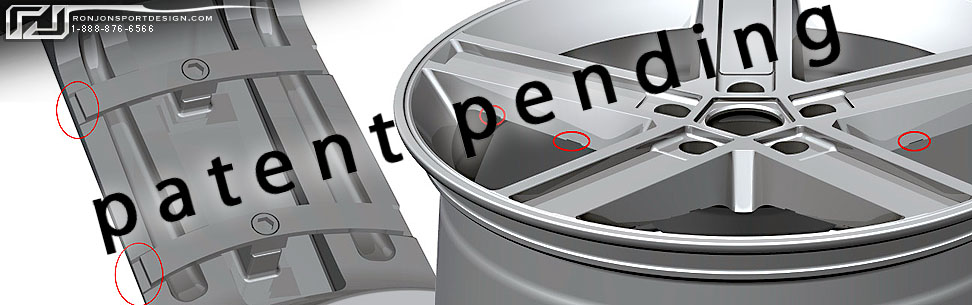

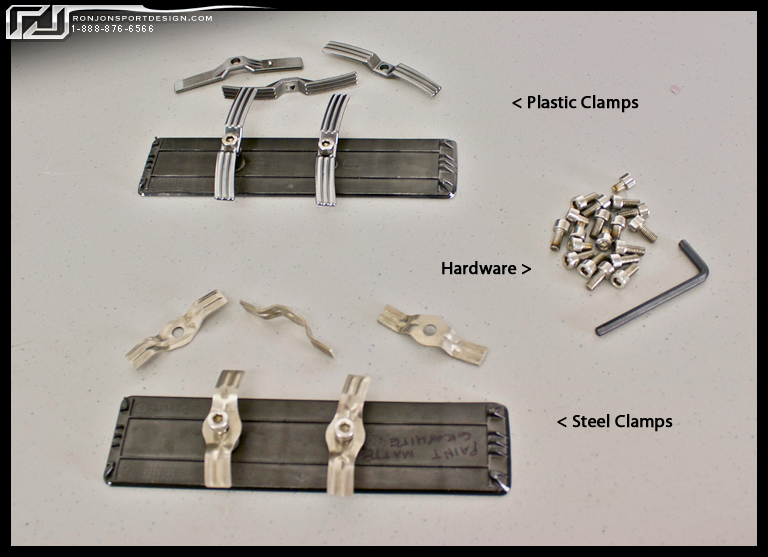

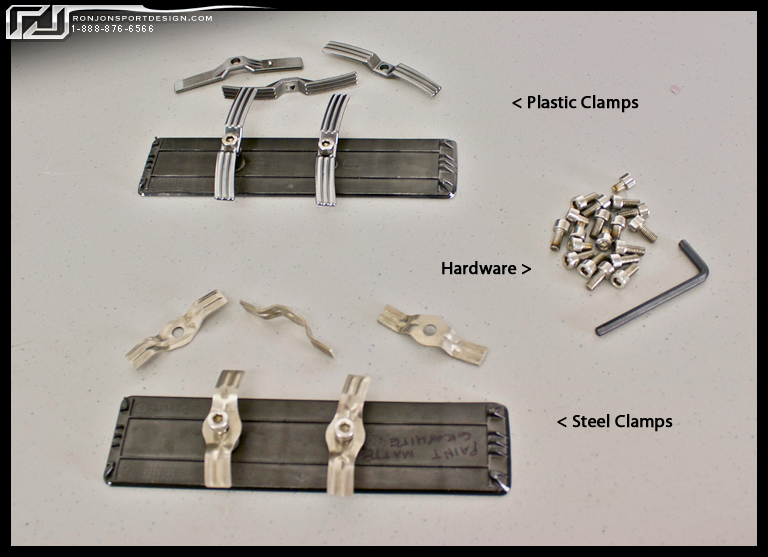

Step Four: Engineer the hidden hardware to perform efficiently

Initially, I suggested screws behind the wheel to fasten the inserts so the hardware would be hidden. But that was too risky since multiple holes would cause potential structural weakness. Also, caliper clearance would be sacrificed if the screws became loose later on. We agreed that the clamp system would be the best way to do it. The plastic clamps were designed and built right away. But those were tested and failed the high speed test since they had too much flex. A multi-stage stamping process was used to make the same clamps out of steel to prevent the flex. Those did pass the high speed test.

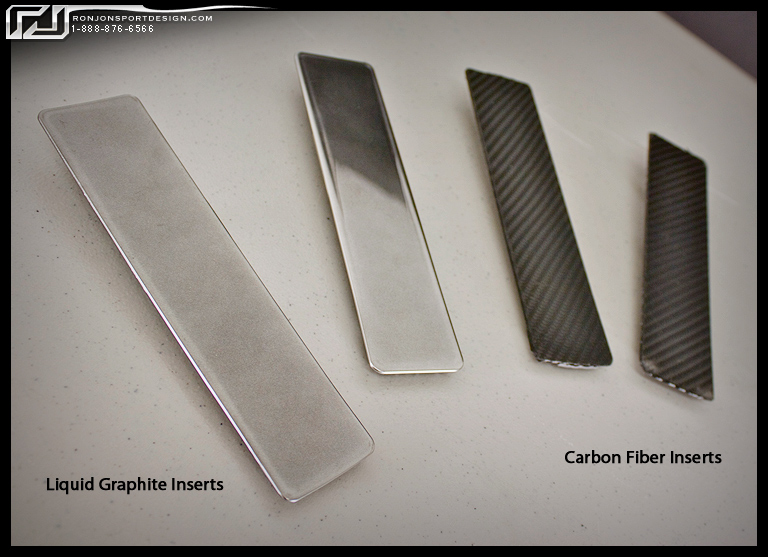

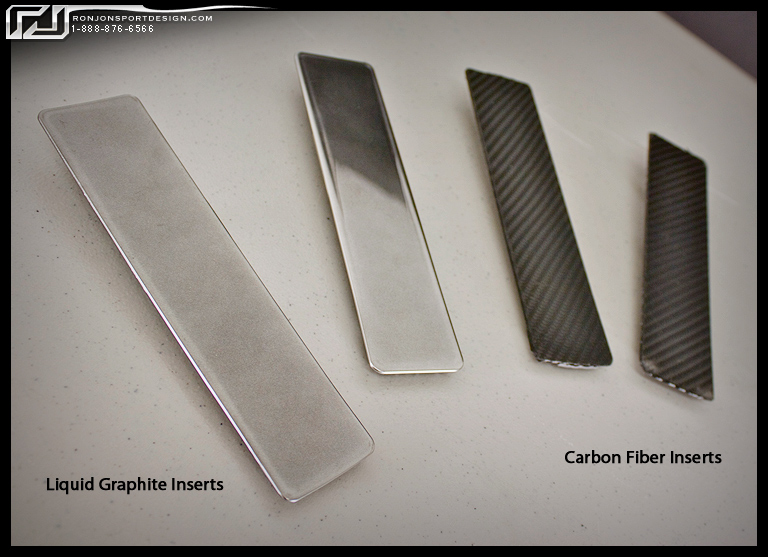

Below are the CGI of the concept inserts followed by two samples of the clamps we developed together, the failed plastic ones and the successful steel ones. Pics on the wheel coming next.

Inserts can be custom finished to blend in with the wheel or to offer contrast.

Step Four: Engineer the hidden hardware to perform efficiently

Initially, I suggested screws behind the wheel to fasten the inserts so the hardware would be hidden. But that was too risky since multiple holes would cause potential structural weakness. Also, caliper clearance would be sacrificed if the screws became loose later on. We agreed that the clamp system would be the best way to do it. The plastic clamps were designed and built right away. But those were tested and failed the high speed test since they had too much flex. A multi-stage stamping process was used to make the same clamps out of steel to prevent the flex. Those did pass the high speed test.

Below are the CGI of the concept inserts followed by two samples of the clamps we developed together, the failed plastic ones and the successful steel ones. Pics on the wheel coming next.

Inserts can be custom finished to blend in with the wheel or to offer contrast.

Last edited by rondog; 08-16-2013 at 04:55 PM.

#19

'08 MX5 GT 6spd.

Awesome write up, Rondy. I love the angular designs on your wheels....I still think the Servo was a fantastic looking wheel. I miss looking at me CL in the driveway with them. I wish you had some light weight options

#20

Step Five: Mold making of the low pressure cast aluminum mold & structural testing

So the design and engineering of the wheel was finalized and confirmed for approval. The molds were built and a prototype sample wheel was produced. We ordered two finishes and while those two samples were sent to us for photography and inspection, the other samples were being tested in a variety of different ways all approved by JWL and VIA certified factory standards. Below are images of the mold parts, a sample wheel images out of the mold and the passed test results.

There are a wide variety of physical tests that apply. These are actual tests, not computer simulated tests. They literally drop calculated weighted objects onto the wheel fitted with a tire in a fashion to replicate accidental damage to ensure load rating and structural integrity. Without getting into a multipage post, some brief descriptions of the tests that take place are:

Due to confidentiality, I am not able to post the particulars of the results.

So the design and engineering of the wheel was finalized and confirmed for approval. The molds were built and a prototype sample wheel was produced. We ordered two finishes and while those two samples were sent to us for photography and inspection, the other samples were being tested in a variety of different ways all approved by JWL and VIA certified factory standards. Below are images of the mold parts, a sample wheel images out of the mold and the passed test results.

There are a wide variety of physical tests that apply. These are actual tests, not computer simulated tests. They literally drop calculated weighted objects onto the wheel fitted with a tire in a fashion to replicate accidental damage to ensure load rating and structural integrity. Without getting into a multipage post, some brief descriptions of the tests that take place are:

- Fatigue tests

- Impact tests

- Cornering tests

- Salt test

Due to confidentiality, I am not able to post the particulars of the results.

#21

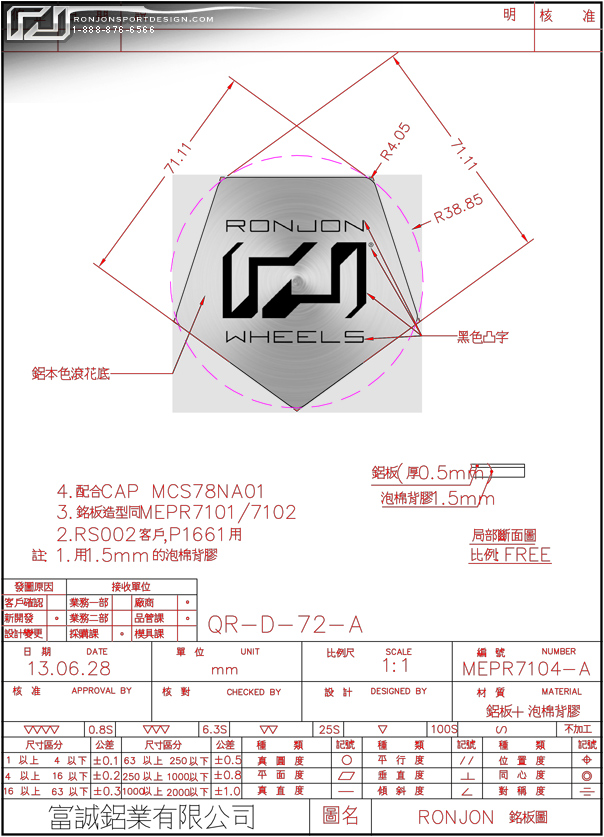

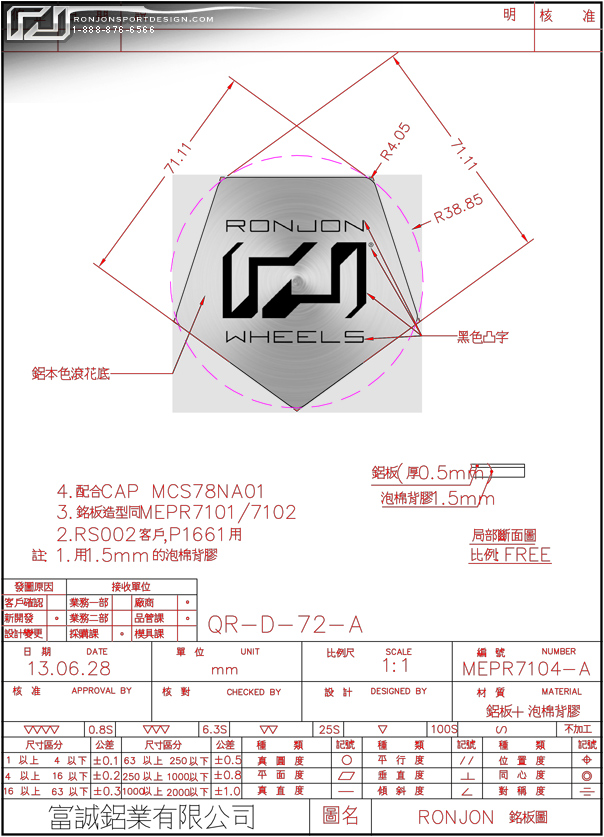

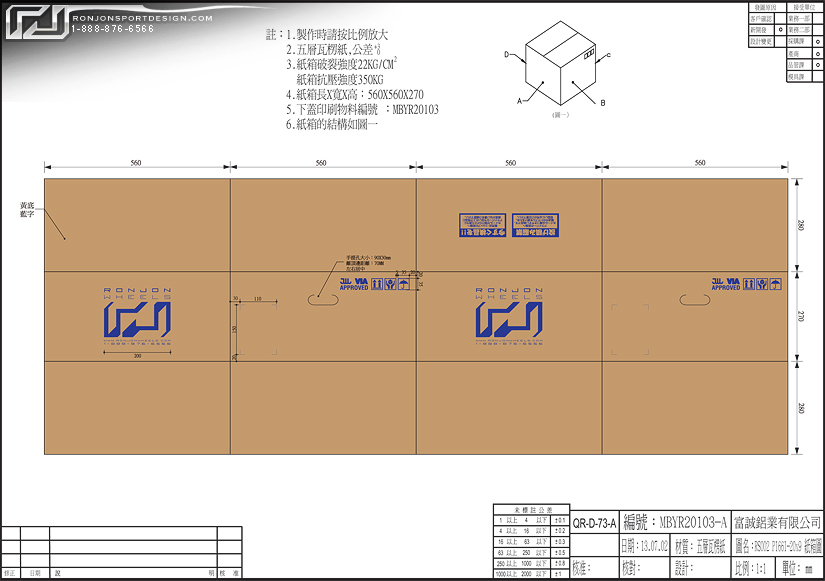

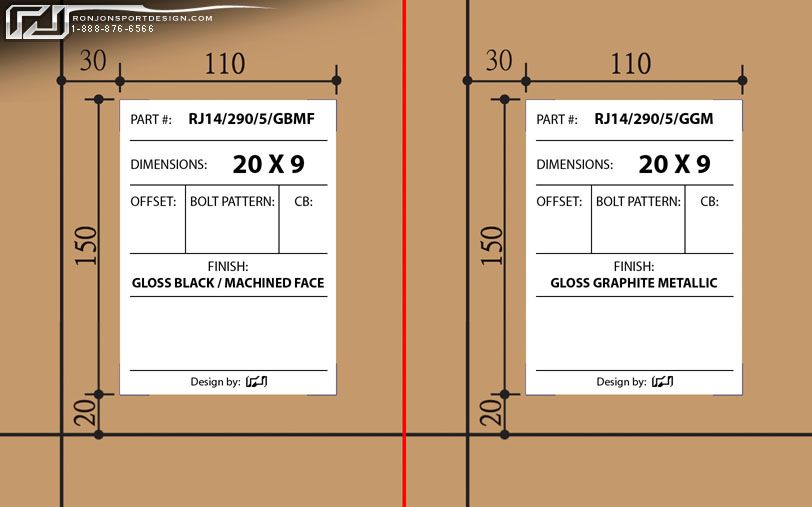

Step Six: Centercap design and packaging

This new version of the Inspyre type II has a new pentagon centercap design that I feel works well with the angular design of the wheel. A clear view of the logo and metallic texture of turned aluminum in the background offer contrast and clarity. We also have a traditional circular center cap for those who want to switch it up.

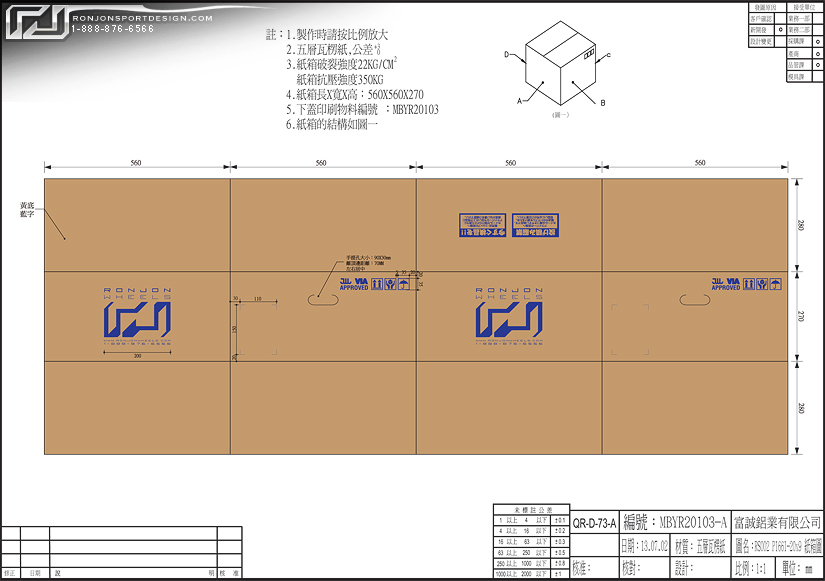

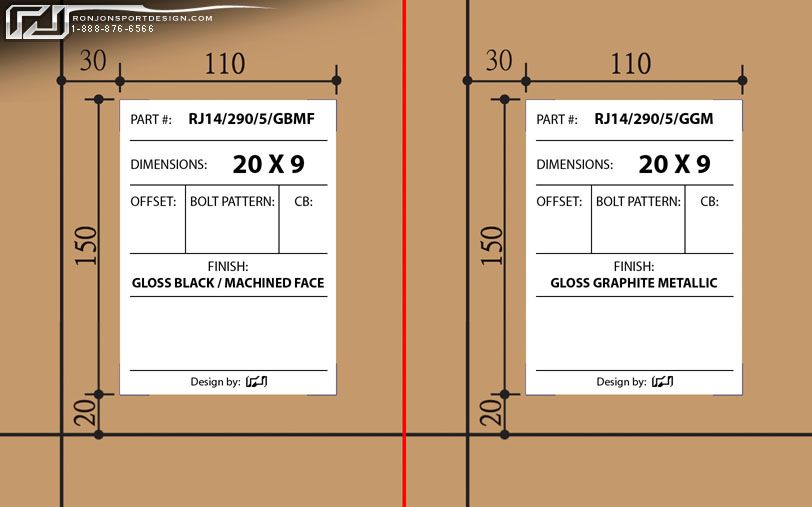

Packaging should be done in a way that it is representing an authentic product and identifiable in a warehouse filled with hundreds of boxes. Simple logo with complimentary colors and company info will do the trick. Nothing crazy, yet unique. Labels for boxes should also be easily distinguished when sifting for part numbers.

This new version of the Inspyre type II has a new pentagon centercap design that I feel works well with the angular design of the wheel. A clear view of the logo and metallic texture of turned aluminum in the background offer contrast and clarity. We also have a traditional circular center cap for those who want to switch it up.

Packaging should be done in a way that it is representing an authentic product and identifiable in a warehouse filled with hundreds of boxes. Simple logo with complimentary colors and company info will do the trick. Nothing crazy, yet unique. Labels for boxes should also be easily distinguished when sifting for part numbers.

#22

Team Owner

iTrader: (2)

Join Date: Jan 2008

Location: Kansas City, MO (Overland Park, KS)

Posts: 36,545

Received 6,470 Likes

on

5,162 Posts

Damn.....those center caps look great.

#25

Drifting

#26

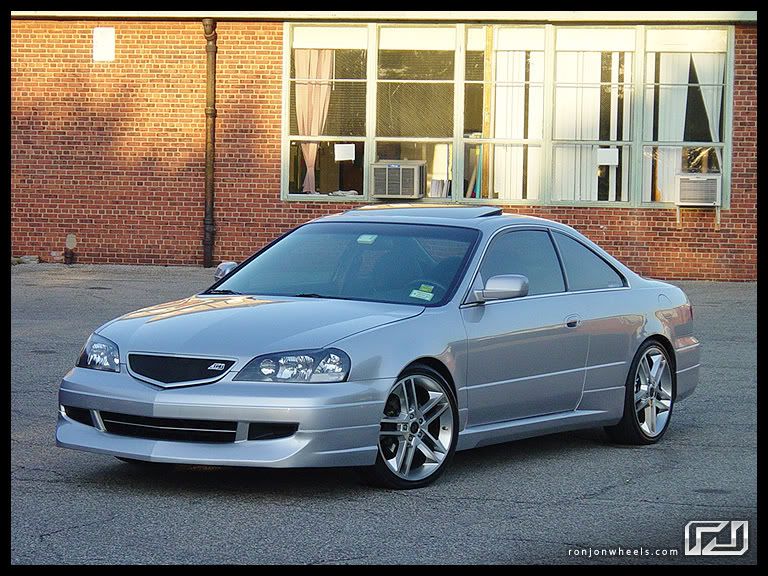

Step Seven: Initial photoshoots of sample wheels

Sample prototypes are photographed in studio and on location to be used on the website, in social media sites, advertising, etc. Inserts are also custom finished and shot as well. There are more images coming soon as soon as production wheels arrive.

Sample prototypes are photographed in studio and on location to be used on the website, in social media sites, advertising, etc. Inserts are also custom finished and shot as well. There are more images coming soon as soon as production wheels arrive.

#30

Wheel turned out nice.

Congrats.

Congrats.

#32

Team Owner

iTrader: (2)

Join Date: Jan 2008

Location: Kansas City, MO (Overland Park, KS)

Posts: 36,545

Received 6,470 Likes

on

5,162 Posts

Rondy, believe it or not, but I think I like them better without the Carbon Fiber insets......

Thread

Thread Starter

Forum

Replies

Last Post

DunesCreations

3G TL Tires, Wheels & Suspension

13

09-09-2015 12:03 PM

and they must be pot hole proof too.

and they must be pot hole proof too.

I like the graphite, as well, with or without the inserts.

I like the graphite, as well, with or without the inserts.