Brembo bolts came out perfectly! Now what? Anti-Seize or Not?

#1

Mods feel free to delete or merger this if it's considered superfluous on it's own.

So many of you know I've been fearing doing the front brakes on my 05 MT because of all the horror stories. But I finally needed to do them. Never touched the caliper bolts in 12 years but they came out perfectly. Seriously, they look brand new. I decided no-guts, no glory, and used my electric impact wrench. As soon as they cracked free I could just about take them out by hand. Perhaps being a garaged car and working from home the last 6 years had something to do with it. No signs of any thread locker on the bolts either.

So now the question is do I just put them back in as they came out (at spec torque)? or do I use some anti-seize or grease and lower the torque accordingly (if lower how much)? I'd like to think I won't be doing this job ever again but still wonder if putting something on the threads is a good idea just in case. What do you think?

The set disc set/retaining screws, not so much. I was a little overzealous drilling one so let's just leave it at the passenger side will only have one set screw from here on out. Glad I didn't break the seal on the TimeSert kit so it can go back to Amazon.

So many of you know I've been fearing doing the front brakes on my 05 MT because of all the horror stories. But I finally needed to do them. Never touched the caliper bolts in 12 years but they came out perfectly. Seriously, they look brand new. I decided no-guts, no glory, and used my electric impact wrench. As soon as they cracked free I could just about take them out by hand. Perhaps being a garaged car and working from home the last 6 years had something to do with it. No signs of any thread locker on the bolts either.

So now the question is do I just put them back in as they came out (at spec torque)? or do I use some anti-seize or grease and lower the torque accordingly (if lower how much)? I'd like to think I won't be doing this job ever again but still wonder if putting something on the threads is a good idea just in case. What do you think?

The set disc set/retaining screws, not so much. I was a little overzealous drilling one so let's just leave it at the passenger side will only have one set screw from here on out. Glad I didn't break the seal on the TimeSert kit so it can go back to Amazon.

#2

I've removed my brembo caliper bolts a few times now and never had issues. I think it's just a matter of being extremely cautious. When removing them, I would tap the socket wrench handle with a hammer... instant short bursts of force.

Putting them back in, I simply inserted and twisted them with my fingers. If there was any resistance along the way, I'd back it out gently, check the grooves, blow them out if necessary and go back in. Eventually you'll have to tighten with a socket wrench. The key is to make sure it's smooth at all times.

I also supported the caliper with one hand while screwing the bolt in... tried to make sure there were no unnecessary forces acting on the bolt as it went in. As I've said, I haven't had any issues to date.

Putting them back in, I simply inserted and twisted them with my fingers. If there was any resistance along the way, I'd back it out gently, check the grooves, blow them out if necessary and go back in. Eventually you'll have to tighten with a socket wrench. The key is to make sure it's smooth at all times.

I also supported the caliper with one hand while screwing the bolt in... tried to make sure there were no unnecessary forces acting on the bolt as it went in. As I've said, I haven't had any issues to date.

#3

I wouldn't add anything on the threads. You might end up adding more torque than necessary, or simply not enough torque. Being dissimilar metals, with soft as hell aluminum, I don't think it's a good idea.

The following users liked this post:

Adobeman (05-12-2017)

#6

Anti-sieze definitely helps with corrosion between dissimilar metals. And it also helps to better standardize torque-tension values. The tension as a result of torque will be MORE accurate/repeatable.

BUT...the joint has to be designed for greased threads. Meaning, you'll need to derive a tension value from a torque value.

Nah. That shit difficult. But its the best way to do it. I would certainly aim to do that because of the dissimilar metals and shitty midwest driving environment.

To keep it simple, though...if the factory torque procedure doesn't call for anti sieze, you probably want to torque it dry (no grease, clean threads).

I am assuming that over torquing is a likely cause of most failures.

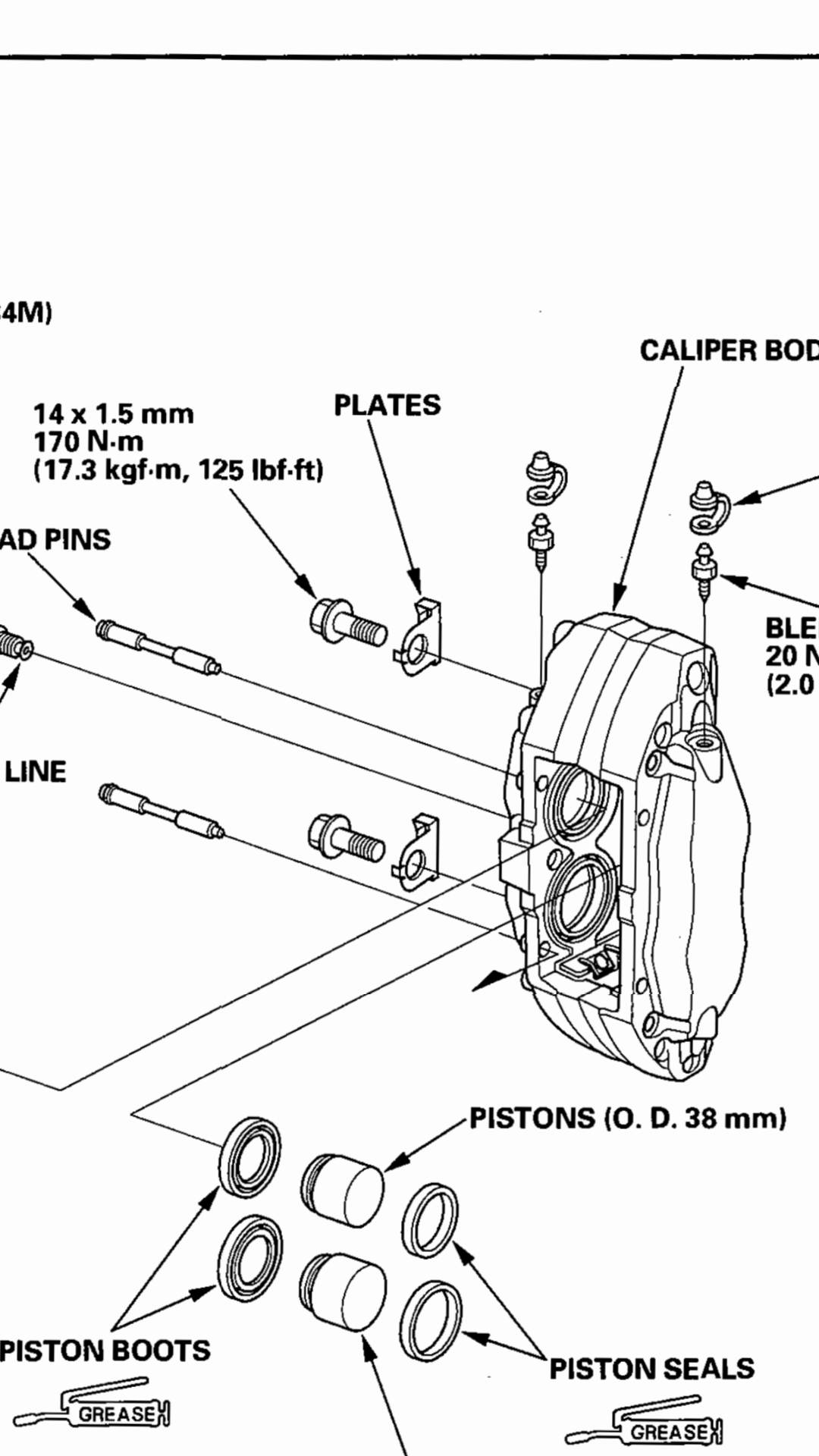

What is the factory torque value anyway? I'm guessing its a M14 bolt and like 60LB or something?

BUT...the joint has to be designed for greased threads. Meaning, you'll need to derive a tension value from a torque value.

Nah. That shit difficult. But its the best way to do it. I would certainly aim to do that because of the dissimilar metals and shitty midwest driving environment.

To keep it simple, though...if the factory torque procedure doesn't call for anti sieze, you probably want to torque it dry (no grease, clean threads).

I am assuming that over torquing is a likely cause of most failures.

What is the factory torque value anyway? I'm guessing its a M14 bolt and like 60LB or something?

Last edited by BROlando; 05-12-2017 at 08:03 PM.

#7

Trending Topics

#8

Ah. 125LB likely because that joint is:

-Steel to aluminum. So a lot of turning force is lost to friction.

-Sees almost no tensile loading.

It is definitely high, though, for an aluminum reciever. You definitely wouldn't want to use 125LB-FT with anti sieze.

-Steel to aluminum. So a lot of turning force is lost to friction.

-Sees almost no tensile loading.

It is definitely high, though, for an aluminum reciever. You definitely wouldn't want to use 125LB-FT with anti sieze.

#9

I'm glad you got yours out with no problem, I would go out and buy a lottery ticket

Instead of anti-seize you can replace both bolts with new ones, they come from the factory with what looks like a hot-dipped zinc coating that should help slow down the dissimilar metal corrosion. After I installed the TimeSert kit on all 4 caliper holes I replaced with new bolts for peace of mind.

Instead of anti-seize you can replace both bolts with new ones, they come from the factory with what looks like a hot-dipped zinc coating that should help slow down the dissimilar metal corrosion. After I installed the TimeSert kit on all 4 caliper holes I replaced with new bolts for peace of mind.

#10

I ended up using A/S on mine when I got them Helicoiled after 3 of 4 threads were shot. I re-torqued to spec completely forgetting about backing it down a bit. I recently had to take both front calipers off and they came off without any issue. There wasn't much evidence of the A/S left so I cleaned out what I could see off the threads and rethreaded them dry @ 125 ft/lbs.