Lightweight Crank Pulley Calcs (Sorry, long read)

#1

Lightweight Crank Pulley Calcs (Sorry, long read)

Hey guys, I've been considering getting a light weight crank pulley and have seen a LOT of threads that go back and forth on this. Lots of claims of "it's great" and "spend the $$$ elsewhere." Anyway, it seems that the calcs for this are very simply, and I'm kind of surprised that no one has done them (at least from what I found). I figure I'd throw some together so maybe people can see what gains people (theoretically) can get.

Here goes...

Assumptions:

1500rpm to 6500rpm @ ~2s (1st gear; assuming linear acceleration)

Pulley diameter = 7.125in (0.5937ft)

Stock pulley weight = 8.0 lbs

Lightweight pulley weight = 15oz = 0.9375 lb (UR Crank Pulley)

Calcs:

Average Torque required to spin stock pulley

T (Torque) = I (Moment of Inertia) * a (angular accelerations)

Moment of Inertia of a cylinder:

I = (mr^2)/2

m = 8.0(lbf)/32.2(ft/s^2) = 0.24844lbm

I = [0.24844lbm*(0.5937ft)^2]/2 = 0.0438 lbm*ft^2

Angular Acceleration:

a = (w2-w1)/t = [(6500rpm*2pi/60) - (1500rpm*2pi/60)]/2s

a = 261.8 rad/s^2

Average Torque:

T=I*a = (0.0438 lbm*ft^2)*(261.8 rad/s^2) = 11.467 lbm*ft^2/s^2

T = 11.467 lbf*ft

Now let me stop right there for a second. This value is obtained assuming a constant linear acceleration from 1500rm to 6500rpm. Since engine acceleration is actually quicker around 1500rpm than it is around 6500rpm, that means that the instantaneous torque around 1500rpm will actually be higher than this and the instantaneous torque around 6500rpm will be lower... without having exact rpm/time data, I can't give you exact numbers.

To move on:

P (Power) = T (Torque) * w (angular velocity)

P = (11.467lbf*ft) * (6500rpm*2pi/60) = 7805.11 lbf*ft/s = 468306.54 lbf*ft/min

P = (468306.54lbf*ft/min)(1hp/33000lbf*ft/min) = 14.19hp

Now to stop again. This value was calculated using the previous average torque, which will NOT be 11.467 @ 6500. Again, hard to say exactly what the value will be without specific data. On a better estimation (ONLY estimation) that average torque would be reasonable ~5000rpm... giving a power value of about 10.91hp @ 5000rpm.

Now to clarify what this means. This is the power that the stock crank pulley REQUIRES to spin from 1500rpm to 6500rpm in about 2 seconds. This is an assumption that will vary on the car/engine/mods/altitude/humidity/etc. If it takes you twice the time, then you're 'losing' half the power. Now this value is the MAXIMUM possible gains you could get on your car from completely not having any sort of pulley.

Now onto lightweight pulleys. I'll make this brief by not breaking down every single calc.

Now the light weight pulley's reduce the weight of the stock pulley by 7 pounds... BUT this is NOT a uniform reduction, and most of the weight is near the outer diameter of the pulley. This still creates a relatively high moment of inertia that does not scale linearly with weight.

In short, I assumed that 80% of the pulley weight is on the outer 20% radius of the pulley. This is me eye-balling this so it's not 100% accurate, but it makes a slight difference nonetheless (~0.5 lbf*ft of torque from uniform calcs).

Anyways:

I = [(0.2*m*(.8r)^2)/2]+[(.8*m*((0.8r)^2+r^2))/2]

m = .9375lbf/(32.3ft/s^2) = 0.291 lbm

r = 0.5937ft

I = 0.00739 lbm *ft^2 (Note how much smaller this is than stock)

a = 261.8 rad/s^2 (Same as before)

T = I*a = (0.00739 lbm*ft^2)*(261.8 rad/s^2) = 1.935 lbm*ft^2/s^2

T = 1.935lbf*ft

To stop again. This is the average torque that is required to spin the lightweight pulley at the same acceleration. Again, the engine is not linear so it will take MORE torque to spin it at lower rpms and less torque to spin it at higher rpms.

Similar to before, if we assume this torque to be accurate @ around 5000rpm:

Power = T * w = (1.935lbf*ft) * (5000rpm*2pi/60) = 1012.97 lbf*ft/s = 60778.66 lbf*ft/min

P = (60778.66lbf*ft/min)(1hp/33000lbf*ft/min) = 1.84hp

Again, this is how much power is required at 5000rpm for the pulley to be accelerated from 1500rpm to 6500rpm in 2 seconds.

To look at average value differences.

T.stkpulley - T.lwpulley = 11.467 - 1.935 = 9.532 lbf*ft

P.stkpulley - P.lwpulley = 10.91 - 1.84 = 9.07 hp

Some more things to clarify. Again these are AVERAGE numbers in first gear. Changing the time assumption as little as 1 second makes a huge difference... 3 seconds from 1500rpm to 6500rpm drop the difference to 6.35lbf*ft/6.04 hp.

This is where the problem comes in... gears. In higher gears, it takes longer for your engine to accelerate, thus less torque/power is required to accelerate the pulley as well. Thus it is not a constant gain, and 100% dependent on your engine acceleration.

Taking a look at the gear ratios for the car (auto) I get 2.697, 1.606, 1.071, 0.693, 0.490 respectively. This will directly affect engine reving speed.

More (avg) calcs (torque in lbf*ft; power in hp):

1st gear:

Torque gain - 9.532

Power gain - 9.07

2nd gear:

Torque gain - 9.532 (1.606/2.697) = 5.675

Power gain - 9.07 (1.606/2.697) = 5.402

3rd gear:

Torque gain - 9.532 (1.071/2.697) = 3.785

Power gain - 9.07 (1.071/2.697) = 3.603

4th gear:

Torque gain - 9.532 (0.693/2.697) = 2.44

Power gain - 9.07 (0.693/2.697) = 2.33

5th gear:

Torque gain - 9.532 (0.490/2.697) = 1.73

Power gain - 9.07 (0.490/2.697) = 1.648

AGAIN, please note these numbers are 100% based on a 2 second 1500rpm to 6500rpm. The calcs were done more for a basis. Check the time yourself. If it takes you 3 seconds to go from 1500rpm to 6500rpm, then multiple the above values by 2/3. If it takes you 4 seconds, multiple by 2/4. So on.

Also, please note that these are BEST CASE RESULTS. It means that most likely in practice (as opposed to theory) you will be below the values shown above. There are a lot of smaller factors that affect the final outcome. Please also note that these are values at the crank (literally) and will thus result in lower WHP numbers.

Please let me know if you feel like I missed something, fat-fingered something, or need to explain something in more detail. Hope this helps. Thanks for the read.

Here goes...

Assumptions:

1500rpm to 6500rpm @ ~2s (1st gear; assuming linear acceleration)

Pulley diameter = 7.125in (0.5937ft)

Stock pulley weight = 8.0 lbs

Lightweight pulley weight = 15oz = 0.9375 lb (UR Crank Pulley)

Calcs:

Average Torque required to spin stock pulley

T (Torque) = I (Moment of Inertia) * a (angular accelerations)

Moment of Inertia of a cylinder:

I = (mr^2)/2

m = 8.0(lbf)/32.2(ft/s^2) = 0.24844lbm

I = [0.24844lbm*(0.5937ft)^2]/2 = 0.0438 lbm*ft^2

Angular Acceleration:

a = (w2-w1)/t = [(6500rpm*2pi/60) - (1500rpm*2pi/60)]/2s

a = 261.8 rad/s^2

Average Torque:

T=I*a = (0.0438 lbm*ft^2)*(261.8 rad/s^2) = 11.467 lbm*ft^2/s^2

T = 11.467 lbf*ft

Now let me stop right there for a second. This value is obtained assuming a constant linear acceleration from 1500rm to 6500rpm. Since engine acceleration is actually quicker around 1500rpm than it is around 6500rpm, that means that the instantaneous torque around 1500rpm will actually be higher than this and the instantaneous torque around 6500rpm will be lower... without having exact rpm/time data, I can't give you exact numbers.

To move on:

P (Power) = T (Torque) * w (angular velocity)

P = (11.467lbf*ft) * (6500rpm*2pi/60) = 7805.11 lbf*ft/s = 468306.54 lbf*ft/min

P = (468306.54lbf*ft/min)(1hp/33000lbf*ft/min) = 14.19hp

Now to stop again. This value was calculated using the previous average torque, which will NOT be 11.467 @ 6500. Again, hard to say exactly what the value will be without specific data. On a better estimation (ONLY estimation) that average torque would be reasonable ~5000rpm... giving a power value of about 10.91hp @ 5000rpm.

Now to clarify what this means. This is the power that the stock crank pulley REQUIRES to spin from 1500rpm to 6500rpm in about 2 seconds. This is an assumption that will vary on the car/engine/mods/altitude/humidity/etc. If it takes you twice the time, then you're 'losing' half the power. Now this value is the MAXIMUM possible gains you could get on your car from completely not having any sort of pulley.

Now onto lightweight pulleys. I'll make this brief by not breaking down every single calc.

Now the light weight pulley's reduce the weight of the stock pulley by 7 pounds... BUT this is NOT a uniform reduction, and most of the weight is near the outer diameter of the pulley. This still creates a relatively high moment of inertia that does not scale linearly with weight.

In short, I assumed that 80% of the pulley weight is on the outer 20% radius of the pulley. This is me eye-balling this so it's not 100% accurate, but it makes a slight difference nonetheless (~0.5 lbf*ft of torque from uniform calcs).

Anyways:

I = [(0.2*m*(.8r)^2)/2]+[(.8*m*((0.8r)^2+r^2))/2]

m = .9375lbf/(32.3ft/s^2) = 0.291 lbm

r = 0.5937ft

I = 0.00739 lbm *ft^2 (Note how much smaller this is than stock)

a = 261.8 rad/s^2 (Same as before)

T = I*a = (0.00739 lbm*ft^2)*(261.8 rad/s^2) = 1.935 lbm*ft^2/s^2

T = 1.935lbf*ft

To stop again. This is the average torque that is required to spin the lightweight pulley at the same acceleration. Again, the engine is not linear so it will take MORE torque to spin it at lower rpms and less torque to spin it at higher rpms.

Similar to before, if we assume this torque to be accurate @ around 5000rpm:

Power = T * w = (1.935lbf*ft) * (5000rpm*2pi/60) = 1012.97 lbf*ft/s = 60778.66 lbf*ft/min

P = (60778.66lbf*ft/min)(1hp/33000lbf*ft/min) = 1.84hp

Again, this is how much power is required at 5000rpm for the pulley to be accelerated from 1500rpm to 6500rpm in 2 seconds.

To look at average value differences.

T.stkpulley - T.lwpulley = 11.467 - 1.935 = 9.532 lbf*ft

P.stkpulley - P.lwpulley = 10.91 - 1.84 = 9.07 hp

Some more things to clarify. Again these are AVERAGE numbers in first gear. Changing the time assumption as little as 1 second makes a huge difference... 3 seconds from 1500rpm to 6500rpm drop the difference to 6.35lbf*ft/6.04 hp.

This is where the problem comes in... gears. In higher gears, it takes longer for your engine to accelerate, thus less torque/power is required to accelerate the pulley as well. Thus it is not a constant gain, and 100% dependent on your engine acceleration.

Taking a look at the gear ratios for the car (auto) I get 2.697, 1.606, 1.071, 0.693, 0.490 respectively. This will directly affect engine reving speed.

More (avg) calcs (torque in lbf*ft; power in hp):

1st gear:

Torque gain - 9.532

Power gain - 9.07

2nd gear:

Torque gain - 9.532 (1.606/2.697) = 5.675

Power gain - 9.07 (1.606/2.697) = 5.402

3rd gear:

Torque gain - 9.532 (1.071/2.697) = 3.785

Power gain - 9.07 (1.071/2.697) = 3.603

4th gear:

Torque gain - 9.532 (0.693/2.697) = 2.44

Power gain - 9.07 (0.693/2.697) = 2.33

5th gear:

Torque gain - 9.532 (0.490/2.697) = 1.73

Power gain - 9.07 (0.490/2.697) = 1.648

AGAIN, please note these numbers are 100% based on a 2 second 1500rpm to 6500rpm. The calcs were done more for a basis. Check the time yourself. If it takes you 3 seconds to go from 1500rpm to 6500rpm, then multiple the above values by 2/3. If it takes you 4 seconds, multiple by 2/4. So on.

Also, please note that these are BEST CASE RESULTS. It means that most likely in practice (as opposed to theory) you will be below the values shown above. There are a lot of smaller factors that affect the final outcome. Please also note that these are values at the crank (literally) and will thus result in lower WHP numbers.

Please let me know if you feel like I missed something, fat-fingered something, or need to explain something in more detail. Hope this helps. Thanks for the read.

The following users liked this post:

paperboy42190 (05-31-2014)

#6

Cool.

But let me ask about this:

You say it seems to you that the UR pulley weight is not uniform across the pulley and so you make and adjustment/assumption for that. But you DO assume that the weight distibution of the stock pulley is linear.

But isn't the same true for the stock pulley?

1.) the hub of that pulley is a concentration of mass.

2.) the material is uniform (I assume, cast iron or whatever), so wouldn't it also concentate mass (mass per unit volume) toward the diameter? IOW - if you took a 1/4" ring out of the pulley near the hub and 1/4" ring near the diameter, the ring from the diameter would weigh quite a bit more. Right?

Oh!! And you forgot the UR Sticker. That adds like 15 HP. Fact.

But let me ask about this:

....

Now the light weight pulley's reduce the weight of the stock pulley by 7 pounds... BUT this is NOT a uniform reduction, and most of the weight is near the outer diameter of the pulley. This still creates a relatively high moment of inertia that does not scale linearly with weight.

In short, I assumed that 80% of the pulley weight is on the outer 20% radius of the pulley. This is me eye-balling this so it's not 100% accurate, but it makes a slight difference nonetheless.....

Now the light weight pulley's reduce the weight of the stock pulley by 7 pounds... BUT this is NOT a uniform reduction, and most of the weight is near the outer diameter of the pulley. This still creates a relatively high moment of inertia that does not scale linearly with weight.

In short, I assumed that 80% of the pulley weight is on the outer 20% radius of the pulley. This is me eye-balling this so it's not 100% accurate, but it makes a slight difference nonetheless.....

But isn't the same true for the stock pulley?

1.) the hub of that pulley is a concentration of mass.

2.) the material is uniform (I assume, cast iron or whatever), so wouldn't it also concentate mass (mass per unit volume) toward the diameter? IOW - if you took a 1/4" ring out of the pulley near the hub and 1/4" ring near the diameter, the ring from the diameter would weigh quite a bit more. Right?

Oh!! And you forgot the UR Sticker. That adds like 15 HP. Fact.

#7

I graduated as a ME and EE, though my work is mainly EE.

Yes and no. Take a look at this pic:

It's a pic of the stock crank pulley the light weight pulley. One thing you'll see in this lightweight pulley (and probably 99% of them) is that the center of the pulley has a lot less material there. Here's a more extreme (though less relevant) pulley to show my point.

This is done for 2 reasons... first is to use less material and cut cost, and second is to reduce weight. But, while weight is being reduced, the most critical weight (near the outside of the pulley) is still mainly there. While my assumption is definitely not 100% correct (and now that I look at it again, 80% seems a bit much), it's mainly there to show that the location of the mass is just as important as the quantity of mass.

But I think your question about inner 1/4" and outer 1/4" is a little off. Like you said, it's a uniform density (mass/volume). Towards the inside you have less volume and less mass in a 1/4" strip and towards the outside you have more volume and more mass in a 1/4" strip... density is still constant in both cases.

The basic moment of inertia equation assumes a constant density with respect to the radius. So for the lightweight pulley I used 20% of the mass for the inner 80% of the radius (solid cylinder) plus 80% of the mass for the 80%+ radius (cylindrical tube). This is just an eye-balling measurement and actually makes a small difference with a 15oz object, compared to an 8lb object.

For instance, assuming both uniformly scale (same shape)... then the moment of inertia would be ~1/8 of stock (1lb/8lbs) giving us 0.00548lbm*ft^2. Required torque would be 1.43 lbf*ft versus the previously calculated 1.93lbf*ft. Percentage wise, it's a decent difference but in the real world, it's not going to be noticed anyway.

Hope that helps.

(BTW, sorry guys for using lbf*ft for torque units everywhere. I know it's usually said "foot-pounds" but I hate working in English units and I'm still stuck on Newton-meters (N*m). Plus I also suck at scaling images in the forums apparently.)

Cool.

But let me ask about this:

You say it seems to you that the UR pulley weight is not uniform across the pulley and so you make and adjustment/assumption for that. But you DO assume that the weight distibution of the stock pulley is linear.

But isn't the same true for the stock pulley?

But let me ask about this:

You say it seems to you that the UR pulley weight is not uniform across the pulley and so you make and adjustment/assumption for that. But you DO assume that the weight distibution of the stock pulley is linear.

But isn't the same true for the stock pulley?

It's a pic of the stock crank pulley the light weight pulley. One thing you'll see in this lightweight pulley (and probably 99% of them) is that the center of the pulley has a lot less material there. Here's a more extreme (though less relevant) pulley to show my point.

This is done for 2 reasons... first is to use less material and cut cost, and second is to reduce weight. But, while weight is being reduced, the most critical weight (near the outside of the pulley) is still mainly there. While my assumption is definitely not 100% correct (and now that I look at it again, 80% seems a bit much), it's mainly there to show that the location of the mass is just as important as the quantity of mass.

But I think your question about inner 1/4" and outer 1/4" is a little off. Like you said, it's a uniform density (mass/volume). Towards the inside you have less volume and less mass in a 1/4" strip and towards the outside you have more volume and more mass in a 1/4" strip... density is still constant in both cases.

The basic moment of inertia equation assumes a constant density with respect to the radius. So for the lightweight pulley I used 20% of the mass for the inner 80% of the radius (solid cylinder) plus 80% of the mass for the 80%+ radius (cylindrical tube). This is just an eye-balling measurement and actually makes a small difference with a 15oz object, compared to an 8lb object.

For instance, assuming both uniformly scale (same shape)... then the moment of inertia would be ~1/8 of stock (1lb/8lbs) giving us 0.00548lbm*ft^2. Required torque would be 1.43 lbf*ft versus the previously calculated 1.93lbf*ft. Percentage wise, it's a decent difference but in the real world, it's not going to be noticed anyway.

Hope that helps.

(BTW, sorry guys for using lbf*ft for torque units everywhere. I know it's usually said "foot-pounds" but I hate working in English units and I'm still stuck on Newton-meters (N*m). Plus I also suck at scaling images in the forums apparently.)

Trending Topics

#8

i dont wanna shoot down anything that's been said, but, ummm <scatching head>....

props to the OP for writing all that...thats a lot of fucking work.

Now, OP, the reason you've seen debates going back and forth about the pulley is simply due to the fact that ppl experience the very different results. That's also simple why, bcs ur car will not run the same from hr to hr...a pure stock TL, will have a 10 hp difference often through the day. This is another reason why some ppl swear by certain mods also. Its very easy to almost manipulate urself into believing that a certain mod made a dramatic difference, aside from the seeds of expectations they plant into their own heads. Here's an example:

You're out driving around...suddenly you decide you wanna install that TB spacer and that CAI you've bought but haven't installed yet...you then pull the car in your garage/driveway...shut it off and pop the hood, but after u touch a few things, you notice its too freaking hot to work on it, so u leave the TB alone and let it cool down a bit and start at the bumper first...so by the time you're all done..few hrs have passed, and the car engine is once again at ambient temp...so u decide to start the baby up and go for a ride, and see what feels different.

You can't believe what the CAI and TB spacer just did...turned it in a monster rocket...

ever drive right after start up and it feels so much better than after having driven it for a while? ok, so you get the picture now... and believe me, ppl experience this very scenario very often and dont realize it. Same thing will happen to someone with the pulley!, but ill leave that alone for now. That was just a simple silly example....not to mention the changes in motor behavior throughout the day.

Now, I wanna know how you figure that engine acceleration is quicker around 1500 than 6500....

In neutral, this isnt true, and it neither is in the same gear at 1500 and at 6500, or even in a higher gear at 6500 and lower gear around 1500 (try it for urself)

really, the only gear that you "could", and i can't stress enough, the possibility that you*could* feel the difference of that pulley is 1st gear!

next thing...why didn't you do calculations on the underdrive lightweight pulley. It will be driving all accessories at a slower speed. The reduction in pulley sizes now reduces stress on the engine as well, so that should be something to be considered...and last thing, the 8lbs of the stock pulley need to be taken into consideration as well, as just weight being hauled around.

one more thing i have to point out...the ECM. Dont you think that it changes parameters to meet certain pre-configurations?

here's a simple example... You know we have a power steering pressure switch, a couple feet away from the pump, which plugs in the high pressure steering hose. (I don't know if i wanna assume whether you know what it does and how it works, but ill lay it out anyway)

when you turn ur steering, it demands pressure, the pump is at work, but at that point you're asking for more...so what happens now, the pump puts a load on the engine. The engine needs to maintain that constant state, so the ECM now bumps up the throttle a little, to compensate. I'm sure you have experienced this "you're sitting in the car while at idle, and u move the steering, and suddenly you see the rpm drop and they go back up to normal" ....by now, you're probably asking, what does this have to do with the pulley?

Simple....at idle the engine requires a certain amount of power to maintain a steady 750 rpm ...this is accomplished with specified throttle opening (IAC), specified timing, based on coolant temp, IAT, fuel etc...all working together to maintain a set HP required to keep that motor spinning at 750 (or wherever, when you hold the throttle at certain rpm)

so now you know that when you add a sudden amount of load to it (ac/steering), it will compensate by changing parameters...and when that load is taken off, such parameters are no longer needed, so the ECM changes them back to their minimal state to maintain that certain amount of power required for the duty (such as simple idle)

dont you think the same holds true for taking load off the motor?

don't you think the ECM is doing exactly what i mentioned? in the case of the pulley, the motor's simply working less. Why does it always have to be a case of released power, rather than balance at the cost of less work

I think some may already get the picture...as hard as it is to swallow the fact that some things, really dont make a difference sometimes....sometimes it is also how reality just rolls

one day, when i run out of ideas of what to do with my car, i might consider a pulley...untill then, i will do what Bearcat said...keep adding stickers lol

props to the OP for writing all that...thats a lot of fucking work.

Now, OP, the reason you've seen debates going back and forth about the pulley is simply due to the fact that ppl experience the very different results. That's also simple why, bcs ur car will not run the same from hr to hr...a pure stock TL, will have a 10 hp difference often through the day. This is another reason why some ppl swear by certain mods also. Its very easy to almost manipulate urself into believing that a certain mod made a dramatic difference, aside from the seeds of expectations they plant into their own heads. Here's an example:

You're out driving around...suddenly you decide you wanna install that TB spacer and that CAI you've bought but haven't installed yet...you then pull the car in your garage/driveway...shut it off and pop the hood, but after u touch a few things, you notice its too freaking hot to work on it, so u leave the TB alone and let it cool down a bit and start at the bumper first...so by the time you're all done..few hrs have passed, and the car engine is once again at ambient temp...so u decide to start the baby up and go for a ride, and see what feels different.

You can't believe what the CAI and TB spacer just did...turned it in a monster rocket...

ever drive right after start up and it feels so much better than after having driven it for a while? ok, so you get the picture now... and believe me, ppl experience this very scenario very often and dont realize it. Same thing will happen to someone with the pulley!, but ill leave that alone for now. That was just a simple silly example....not to mention the changes in motor behavior throughout the day.

Now, I wanna know how you figure that engine acceleration is quicker around 1500 than 6500....

In neutral, this isnt true, and it neither is in the same gear at 1500 and at 6500, or even in a higher gear at 6500 and lower gear around 1500 (try it for urself)

really, the only gear that you "could", and i can't stress enough, the possibility that you*could* feel the difference of that pulley is 1st gear!

next thing...why didn't you do calculations on the underdrive lightweight pulley. It will be driving all accessories at a slower speed. The reduction in pulley sizes now reduces stress on the engine as well, so that should be something to be considered...and last thing, the 8lbs of the stock pulley need to be taken into consideration as well, as just weight being hauled around.

one more thing i have to point out...the ECM. Dont you think that it changes parameters to meet certain pre-configurations?

here's a simple example... You know we have a power steering pressure switch, a couple feet away from the pump, which plugs in the high pressure steering hose. (I don't know if i wanna assume whether you know what it does and how it works, but ill lay it out anyway)

when you turn ur steering, it demands pressure, the pump is at work, but at that point you're asking for more...so what happens now, the pump puts a load on the engine. The engine needs to maintain that constant state, so the ECM now bumps up the throttle a little, to compensate. I'm sure you have experienced this "you're sitting in the car while at idle, and u move the steering, and suddenly you see the rpm drop and they go back up to normal" ....by now, you're probably asking, what does this have to do with the pulley?

Simple....at idle the engine requires a certain amount of power to maintain a steady 750 rpm ...this is accomplished with specified throttle opening (IAC), specified timing, based on coolant temp, IAT, fuel etc...all working together to maintain a set HP required to keep that motor spinning at 750 (or wherever, when you hold the throttle at certain rpm)

so now you know that when you add a sudden amount of load to it (ac/steering), it will compensate by changing parameters...and when that load is taken off, such parameters are no longer needed, so the ECM changes them back to their minimal state to maintain that certain amount of power required for the duty (such as simple idle)

dont you think the same holds true for taking load off the motor?

don't you think the ECM is doing exactly what i mentioned? in the case of the pulley, the motor's simply working less. Why does it always have to be a case of released power, rather than balance at the cost of less work

I think some may already get the picture...as hard as it is to swallow the fact that some things, really dont make a difference sometimes....sometimes it is also how reality just rolls

one day, when i run out of ideas of what to do with my car, i might consider a pulley...untill then, i will do what Bearcat said...keep adding stickers lol

#9

You bring up a lot of good points. Some of which I can address, some of which I'm probably not fit to. I want to explain that I'm a mechanical engineer not an auto expert. The calcs were simply there to show what results a lightweight pulley COULD create (a theoretical maximum) and wrote a little disclaimer near the end saying that actual results would most likely be lower.

As far as the CAI and TB spacer... that's not really the point of my post. You could say the same thing of driving your car on cool night and it feels like a beast, then you install the CAI/TB spacer and drive the car on a hot, humid day and it feels like you actually lost power. The point of this was to show that regardless of the butt dyno showing different results as different times, the calcs show that you should see an increase in performance (all other things being equal of course).

On to the reving speed... It's really a question of kinetic energy to tell you the truth. I'll use a linear example to show my point (easier to understand than rotational).

Does it take the same energy for a car to go from 0mph to 20 mph as it does to go from 20mph to 40mph? Not having experience with a car, most people say "yeah, it's just a 20 mph difference." But it actually comes down to kinetic energy.

Ek = 1/2*m*v^2

That's half of the mass times the velocity squared. So in each case (0-20 and 20-40), mass is the same so I'll leave it as a variable. To calculate, you take the kinetic energy at the final speed minus the kinetic energy at the initial speed.

Ek.0-20 = 1/2*m*(20^2)-1/2*m*(0^2) = 200*m

Ek.40-20 = 1/2*m*(40^2)-1/2*m* (20^2) = 700*m

So the ratio actually shows that it takes 3.5 times the energy to go from 20-40 as it does from 0-20. This can drastically be seen if you take a look at a car's 0-60 time vs it's 60-120 time (though at these speeds drag is also heavily at play since it's also based on velocity^2).

This concept applies to the car in the same way. The engine actually takes more energy to accelerate at higher rpms. And while more fuel is dumped to account for that energy, there is a limit. Try it in a more noticable (slower) gear like 4th or 5th on a highway. You'll notice that accelerating (at higher speeds) will show a quicker rev near the lower rpms and a slower rev near the higher rpms. Again, this is from a mechanical point of view and the car in practice might actually be able to supply enough energy (fuel) to keep the rise linear, but since the energy required is the square of (angular) velocity, it would quickly need to start dumping pretty significant amount of fuel.

The undersized pulley actually makes a fairly small difference believe it or not. As far as moment of inertia, it's a 15% or 20% radius reduction. While this will result is a decently lower moment of inertia (since radius is squared) your required power/torque is already so small that at most it will make a ~0.5lbf*ft of torque difference. Again, percentage wise it's decent... but nothing you'll even notice.

As far as driving loads, that is actually not as helpful as you might think. If you've played with an alternator assembly and you give it a quick spin, it will free-spin for ~30s. The bearings reduce friction and it's a magnetically coupled device (friction being very minimal). While it's true that as it generates energy, the magnetic fields will actually resist its spinning, it should be fairly minimal for the power it provides. As far as the A/C, as far as I know it's similar to a clutch-type setup (please correct me if I'm wrong). Meaning that if the A/C is off, there is basically no load on the engine from it. You probably shouldn't be racing/sprinting with your A/C blaring anyway. It's easier to press the "OFF" button rather than get a smaller pulley.

I really can't speak for the pump because I'm not 100% familiar with the in-and-outs of how the car responds to load changes in the power steering pump. Sorry, maybe someone else can shed some light on this.

Again to re-state this, it was merely just to show the mechanical power that would become available from a reduced pulley weight. This will also effect several other things I haven't even included in the original post. Theoretically, the lighter weight would also allow the car to rev-match faster and thus shift faster (though again, not 100% sure how the car reacts in actuality). On the downside a heavier rotating mass actually stores more kinetic energy which can be utilized and beneficial ways. A fly-wheel for instance can stores extra energy that makes for a stronger launch. Again, there are a lot of things I haven't included (and probably even more that I'm not aware of), but this was just strictly to show the math/science and what the pulley can achieve.

That being said, I'm not trying to sell this product by any means. Personally, $$/hp, it seems like the J-pipe is still a better (first) buy since it's more linear with rpm/load on the engine (constant gains regardless of which gear you're in) as opposed to the crank pulley which has progressively worse results as engine speed and gears increase.

Hope this cleared some things up. Again, let me know if this wasn't very clear.

As far as the CAI and TB spacer... that's not really the point of my post. You could say the same thing of driving your car on cool night and it feels like a beast, then you install the CAI/TB spacer and drive the car on a hot, humid day and it feels like you actually lost power. The point of this was to show that regardless of the butt dyno showing different results as different times, the calcs show that you should see an increase in performance (all other things being equal of course).

On to the reving speed... It's really a question of kinetic energy to tell you the truth. I'll use a linear example to show my point (easier to understand than rotational).

Does it take the same energy for a car to go from 0mph to 20 mph as it does to go from 20mph to 40mph? Not having experience with a car, most people say "yeah, it's just a 20 mph difference." But it actually comes down to kinetic energy.

Ek = 1/2*m*v^2

That's half of the mass times the velocity squared. So in each case (0-20 and 20-40), mass is the same so I'll leave it as a variable. To calculate, you take the kinetic energy at the final speed minus the kinetic energy at the initial speed.

Ek.0-20 = 1/2*m*(20^2)-1/2*m*(0^2) = 200*m

Ek.40-20 = 1/2*m*(40^2)-1/2*m* (20^2) = 700*m

So the ratio actually shows that it takes 3.5 times the energy to go from 20-40 as it does from 0-20. This can drastically be seen if you take a look at a car's 0-60 time vs it's 60-120 time (though at these speeds drag is also heavily at play since it's also based on velocity^2).

This concept applies to the car in the same way. The engine actually takes more energy to accelerate at higher rpms. And while more fuel is dumped to account for that energy, there is a limit. Try it in a more noticable (slower) gear like 4th or 5th on a highway. You'll notice that accelerating (at higher speeds) will show a quicker rev near the lower rpms and a slower rev near the higher rpms. Again, this is from a mechanical point of view and the car in practice might actually be able to supply enough energy (fuel) to keep the rise linear, but since the energy required is the square of (angular) velocity, it would quickly need to start dumping pretty significant amount of fuel.

The undersized pulley actually makes a fairly small difference believe it or not. As far as moment of inertia, it's a 15% or 20% radius reduction. While this will result is a decently lower moment of inertia (since radius is squared) your required power/torque is already so small that at most it will make a ~0.5lbf*ft of torque difference. Again, percentage wise it's decent... but nothing you'll even notice.

As far as driving loads, that is actually not as helpful as you might think. If you've played with an alternator assembly and you give it a quick spin, it will free-spin for ~30s. The bearings reduce friction and it's a magnetically coupled device (friction being very minimal). While it's true that as it generates energy, the magnetic fields will actually resist its spinning, it should be fairly minimal for the power it provides. As far as the A/C, as far as I know it's similar to a clutch-type setup (please correct me if I'm wrong). Meaning that if the A/C is off, there is basically no load on the engine from it. You probably shouldn't be racing/sprinting with your A/C blaring anyway. It's easier to press the "OFF" button rather than get a smaller pulley.

I really can't speak for the pump because I'm not 100% familiar with the in-and-outs of how the car responds to load changes in the power steering pump. Sorry, maybe someone else can shed some light on this.

Again to re-state this, it was merely just to show the mechanical power that would become available from a reduced pulley weight. This will also effect several other things I haven't even included in the original post. Theoretically, the lighter weight would also allow the car to rev-match faster and thus shift faster (though again, not 100% sure how the car reacts in actuality). On the downside a heavier rotating mass actually stores more kinetic energy which can be utilized and beneficial ways. A fly-wheel for instance can stores extra energy that makes for a stronger launch. Again, there are a lot of things I haven't included (and probably even more that I'm not aware of), but this was just strictly to show the math/science and what the pulley can achieve.

That being said, I'm not trying to sell this product by any means. Personally, $$/hp, it seems like the J-pipe is still a better (first) buy since it's more linear with rpm/load on the engine (constant gains regardless of which gear you're in) as opposed to the crank pulley which has progressively worse results as engine speed and gears increase.

Hope this cleared some things up. Again, let me know if this wasn't very clear.

#12

Former Sponsor

iTrader: (1)

Joined: Mar 2004

Posts: 9,877

Likes: 624

From: www.ExceleratePerformance.com

No. An underdrive pulley underdrives the accessories, which only becomes an issue if you have a large stereo (over 600 watts RMS) or a supercharger. However, if you're concerned about underdrive (of which on average it's only 10-18% on most UR pulleys) then order the stock diameter pulley which is only a few ounces heavier.

#13

#14

Very interesting post Cross-Hair. That really puts things in perspective for me. After getting the UR Lightweight Crank pulley I can definately tell that the engine doesn't have to work as hard to rev. It is more responsive to throttle input and seems to spin the tires much easier off the line. My 0-20MPH is much quicker with less lag. My 60ft dropped at the track by .1 consistantly. The UR pulley is one of the best mods for the money next to my Jpipe!

#15

....

But I think your question about inner 1/4" and outer 1/4" is a little off. Like you said, it's a uniform density (mass/volume). Towards the inside you have less volume and less mass in a 1/4" strip and towards the outside you have more volume and more mass in a 1/4" strip... density is still constant in both cases.

The basic moment of inertia equation assumes a constant density with respect to the radius. ....

But I think your question about inner 1/4" and outer 1/4" is a little off. Like you said, it's a uniform density (mass/volume). Towards the inside you have less volume and less mass in a 1/4" strip and towards the outside you have more volume and more mass in a 1/4" strip... density is still constant in both cases.

The basic moment of inertia equation assumes a constant density with respect to the radius. ....

However, if the MoI equaiton assumes constant density with radius, it doesn't matter - my premise was wrong in the first place.

#17

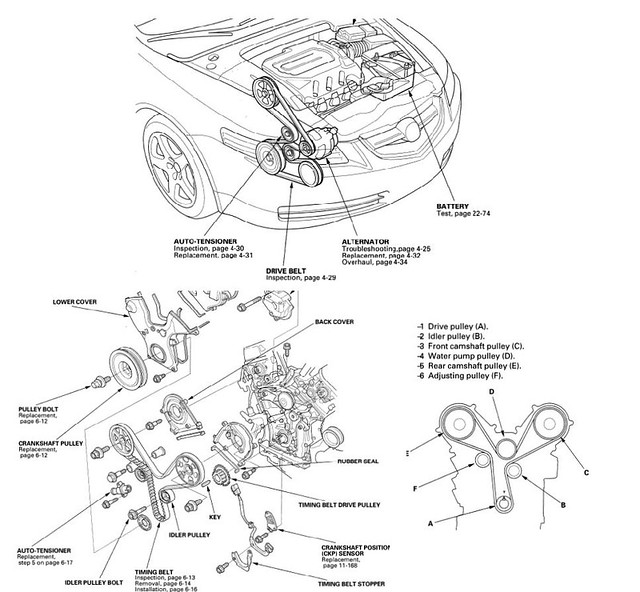

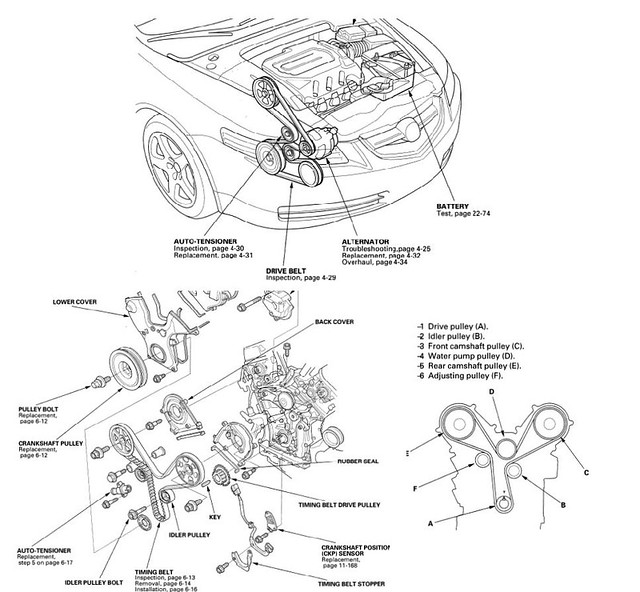

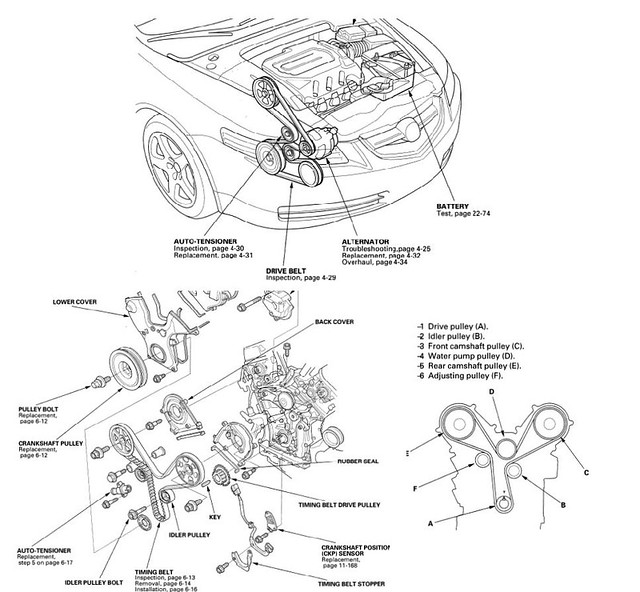

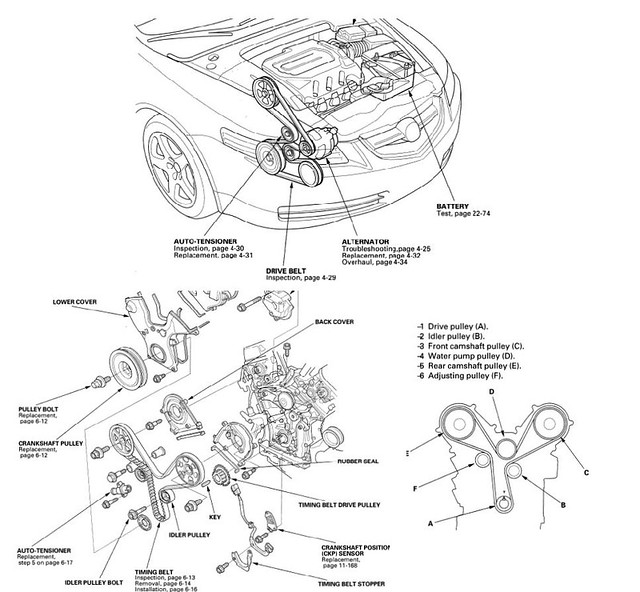

Nice example OP and good post for discussion. I think simple linear calculation examples is only slightly relevant though. Consider the crank not only rotates the mass of the CP which in turn rotates the associated drive assemblies, but it also rotates the cams and related valvetrain components. If you could, try posting a more holistic view relating to the issue. Undoubtedly the lighter CP will be beneficial, but I doubt it's as beneficial as many think it is. I'm not asking for a full out example. A commentary to the discussion would suffice. Here's a belt diagram for your review:

#18

#20

Nice example OP and good post for discussion. I think simple linear calculation examples is only slightly relevant though. Consider the crank not only rotates the mass of the CP which in turn rotates the associated drive assemblies, but it also rotates the cams and related valvetrain components. If you could, try posting a more holistic view relating to the issue. Undoubtedly the lighter CP will be beneficial, but I doubt it's as beneficial as many think it is. I'm not asking for a full out example. A commentary to the discussion would suffice. Here's a belt diagram for your review:

However, friction between rolling surfaces is generally small and make almost no difference in the equations the OP showed. BUT having the A/C on adds resistance to the belt and creates alot of friction on the belt. That could be enough to significantly reduce the power gained by the UR pulley. As we all know, the car is slower with the A/C on. This is why. Friction.

Last edited by NCTL05; 09-02-2010 at 09:19 PM.

#21

I don't think you can take that theoretical torque gain and apply it to an engine under load. You can to a degree but gains are pretty much immeasurable especially the slower it revs.

To take it a step farther, I've replaced the 12" lockup torque convertor on my GN with a 9" non lock. I shaved 25+lbs off the crank. It revs like an Indy car yet no change on the dyno. 1/4 mph remained +-2mph. Et of course went way down but due to other factors.

To take it a step farther, I've replaced the 12" lockup torque convertor on my GN with a 9" non lock. I shaved 25+lbs off the crank. It revs like an Indy car yet no change on the dyno. 1/4 mph remained +-2mph. Et of course went way down but due to other factors.

#22

Cross-Hair, i know what the point of your post is, and I understand you're a mechanical engineer (i respect you for that, and there's no doubt in my mind about the calculations)

I'm not an auto expert either...in fact, im just some guy who decided to mess around with his TL...

i know this had nothing to do with TB spacers or CAIs and so on..it was merely an example of why people debate the LWP. Some swear by it, some are confused, and some dont find anything in it.

And this whole "engine acceleration", do you mean the motor accelerating or the whole car?

Whatever the science behind it is and the energy needed to accelerate at higher revs as opposed to lower revs is completely irrelevant...thats right, mechanically it makes sense as everything you mentioned, but in reality in an engine, thats not what happens. You said it yourself "maybe the engine supplies enough energy to accomplish such at higher rpm". That was exactly my point in my first post.

Mentioning the alternator, PS pump and AC really had nothing to do with the pulley.

I mentioned 2 small examples trying to show how the engine behaves with load (on/off)

While the pulley is not an on/off load...it will be once you change it to a lighter one or vice-versa.

anyway...ill write more later...right now im beat up

I'm not an auto expert either...in fact, im just some guy who decided to mess around with his TL...

i know this had nothing to do with TB spacers or CAIs and so on..it was merely an example of why people debate the LWP. Some swear by it, some are confused, and some dont find anything in it.

And this whole "engine acceleration", do you mean the motor accelerating or the whole car?

Whatever the science behind it is and the energy needed to accelerate at higher revs as opposed to lower revs is completely irrelevant...thats right, mechanically it makes sense as everything you mentioned, but in reality in an engine, thats not what happens. You said it yourself "maybe the engine supplies enough energy to accomplish such at higher rpm". That was exactly my point in my first post.

Mentioning the alternator, PS pump and AC really had nothing to do with the pulley.

I mentioned 2 small examples trying to show how the engine behaves with load (on/off)

While the pulley is not an on/off load...it will be once you change it to a lighter one or vice-versa.

anyway...ill write more later...right now im beat up

#24

I don't think you can take that theoretical torque gain and apply it to an engine under load. You can to a degree but gains are pretty much immeasurable especially the slower it revs.

To take it a step farther, I've replaced the 12" lockup torque convertor on my GN with a 9" non lock. I shaved 25+lbs off the crank. It revs like an Indy car yet no change on the dyno. 1/4 mph remained +-2mph. Et of course went way down but due to other factors.

To take it a step farther, I've replaced the 12" lockup torque convertor on my GN with a 9" non lock. I shaved 25+lbs off the crank. It revs like an Indy car yet no change on the dyno. 1/4 mph remained +-2mph. Et of course went way down but due to other factors.

Exactly the difference under load. Which is why I said, 1st gear is where you might get something.

Thank you!

#25

IOW - since the only change is in weight of the two pulleys, that is where the difference in effect will be.

:bestguess:

#26

Why the crank pulley is reported as "immeasurable" is exactly like you said... heavy load. Correct me if I'm wrong, but most dyno runs are done in 3rd & 4th gear. According to my calcs, that's an (average) gain of 3.7ft*lbf and 2.2ft*lbf at the crank. At the wheels this is even more negligible. Very easy to chock this up to temperature, moisture, dyno error, etc. Either way, even in completely identical environments, chances are these numbers would not be felt by the butt dyno anyway. Dyno'ing the car in 1st gear before and after the pulley should produce noticeable results (though no one is going to do this). BTW, this isn't aimed at you IHC by any means, I'm just expanding on your comment.

We know that torque (with respect to rpm) increases, hits a peak, and then decreases. Torque is your moment of inertia times your angular acceleration. Moment of inertia is constant for a given object. Since Torque vs rpm is not linear, that means that angular acceleration vs rpm cannot be linear.

That being said, my average numbers are still correct (and still just average). However, the peak torque 'gain' from the lightweight pulley will actually happen at the max torque rpm (when the crank shaft is accelerating the fastest), not necessarily at the lowest rpm.

#27

Sorry, I shouldn't have worded it that way. I can see how that's confusing. To put it in a simpler way...

We know that torque (with respect to rpm) increases, hits a peak, and then decreases. Torque is your moment of inertia times your angular acceleration. Moment of inertia is constant for a given object. Since Torque vs rpm is not linear, that means that angular acceleration vs rpm cannot be linear.

That being said, my average numbers are still correct (and still just average). However, the peak torque 'gain' from the lightweight pulley will actually happen at the max torque rpm (when the crank shaft is accelerating the fastest), not necessarily at the lowest rpm.

We know that torque (with respect to rpm) increases, hits a peak, and then decreases. Torque is your moment of inertia times your angular acceleration. Moment of inertia is constant for a given object. Since Torque vs rpm is not linear, that means that angular acceleration vs rpm cannot be linear.

That being said, my average numbers are still correct (and still just average). However, the peak torque 'gain' from the lightweight pulley will actually happen at the max torque rpm (when the crank shaft is accelerating the fastest), not necessarily at the lowest rpm.

#28

The slight problem with the calcs above, is that for them to be more accurate it needs to be iterated many times. It's clear that the faster objects rotate, the more torque they require.

When you reduce the weight of the pulley, the shaft (and all attached accessories) spin faster... faster spin means more torque in ALL of the attachments.

Simply put, the torque you save by reducing to the lightweight pulley gets redistributed to the rest of the system proportionally. Since the wheels require/use the most torque, they receive the biggest % of that freed up torque. But the smaller accessories will also get a small amount.

This is a pain to fully account for (iteration; not something I want to do a step-by-step for) and a huge majority of the freed up torque WILL go to the wheels. That said I stick to my original line:

"Please note that these are BEST CASE RESULTS. It means that most likely in practice (as opposed to theory) you will be below the values shown above. There are a lot of smaller factors that affect the final outcome."

My approximation (without full calcs) is that you should get an average torque of ~6.8ft*lbf to the wheels throughout first gear, with the peak "gains" @ 5000rpm.

#29

I'm interested in hearing a Mechanical engineer's side on this... Say you have a 20lb pulley and a 5lb pulley, does it take more power or the same power to keep the 20lb spinning once it's up to speed. This assumes all else is equal.

By the last reply I kind of get the idea that you're leaning toward more power to keep it at a steady state rpm.

This doesn't apply to mine anyway, it accelerates so slow even in first gear that I would never see the difference.

By the last reply I kind of get the idea that you're leaning toward more power to keep it at a steady state rpm.

This doesn't apply to mine anyway, it accelerates so slow even in first gear that I would never see the difference.

#30

I'm not exactly sure what you mean. The calcs do take into account loading of the engine and should actually be fairly close to real-world numbers that you'll get.

My approximation (without full calcs) is that you should get an average torque of ~6.8ft*lbf to the wheels throughout first gear, with the peak "gains" @ 5000rpm.

My approximation (without full calcs) is that you should get an average torque of ~6.8ft*lbf to the wheels throughout first gear, with the peak "gains" @ 5000rpm.

Yes I know the calcs take into account the loading of the engine...6.8 lbf throughout 1st gear, and almost non existent through the rest of gears. This is what I've been saying on every post...1st GEAR IS WHERE YOU SEE SOMETHING measurable.

#31

#32

It's sort of why curb weight affects mpg a lot in the city where you're accelerating a lot but not as much on a flat freeway.

#33

I'm glad someone finally posted up the science regarding lightened pullies. I've been arguing this very thing for years on this site and have even gotten into it with the owner of Unorthrodox racing who swears up and down that their pullies always see 8whp+ on the dyno in 4th gear. It's simply not possible for the very reasons Cross-Hair posted. As I told the owner of UR, the physics are against him. That's when he left the argument.

Is there power to be gained by reducing the pulley weight? Yes, but the power gain varies greatly across the gears. In the 1/4 mile, a car spends very very little time accelerating in 1st gear and even 2nd gear. This is where the major gains are with the pullies. A gain of 9whp and 6whp in 1st and 2nd across the span of around 6 seconds is going to have very little impact on acceleration. The car spends most of the time accelerating in 3rd and some of 4th and the gains are minimal.

Calculate the gains per gear spread out over time across a 1/4 mile run and you'll see that you're TL will be making a mere 2-3whp more than stock. Sorry, that not going to equate to any measureable drop in the ET or MPH improvement.

The argument of moment of inertia comes up as well. I've had a UR pulley on my VQ30 Maxima and it shed the same amount of weight as the one offered from the TL. That car went to the strip a lot and the pulley showed absolutely no improvement in the 1/4 mile with the pulley nor anything on the dyno. It made the car fractionally harder to launch consistently because of the reduced inertia (ie more prong to bog). I removed the pulley after 2 years use and over 40 1/4 mile passes. I ran my best ever AFTER removing the UR pulley. Go figure.

I guess so many gravitate mod because it's easy. Just like catbacks and intakes. And just like many of these mods, the advertized gains are often not there. I got suckered into believing the lightened pulley hype and learned my lesson after trying it at the strip, on the dyno, and understanding the physics behind it.

Is there power to be gained by reducing the pulley weight? Yes, but the power gain varies greatly across the gears. In the 1/4 mile, a car spends very very little time accelerating in 1st gear and even 2nd gear. This is where the major gains are with the pullies. A gain of 9whp and 6whp in 1st and 2nd across the span of around 6 seconds is going to have very little impact on acceleration. The car spends most of the time accelerating in 3rd and some of 4th and the gains are minimal.

Calculate the gains per gear spread out over time across a 1/4 mile run and you'll see that you're TL will be making a mere 2-3whp more than stock. Sorry, that not going to equate to any measureable drop in the ET or MPH improvement.

The argument of moment of inertia comes up as well. I've had a UR pulley on my VQ30 Maxima and it shed the same amount of weight as the one offered from the TL. That car went to the strip a lot and the pulley showed absolutely no improvement in the 1/4 mile with the pulley nor anything on the dyno. It made the car fractionally harder to launch consistently because of the reduced inertia (ie more prong to bog). I removed the pulley after 2 years use and over 40 1/4 mile passes. I ran my best ever AFTER removing the UR pulley. Go figure.

I guess so many gravitate mod because it's easy. Just like catbacks and intakes. And just like many of these mods, the advertized gains are often not there. I got suckered into believing the lightened pulley hype and learned my lesson after trying it at the strip, on the dyno, and understanding the physics behind it.

#35

So I am an ME and agree with all the math and Physics..... what no one has mention here is that We have a massive power plant that has to move a 3500lb car down the strip. one of the easiest mod anyone can do is remove weight from the car. It is by far the cheapest mod you can do. So in turn reducing the weight of the pulley actually helps in overall weight of the car but cost $$$..... this is my two cents.

Example: all those people who add sound systems to there car all it does is adds weight. sure they sound good but it is the worst thing you can to for performance. i have seen some systems add 150lbs.... Wire, subs, amps, capacitors, all add weight....

personally i want the new Jpipe rev3 just for the added sound it might give me......

just a midnight thought

Example: all those people who add sound systems to there car all it does is adds weight. sure they sound good but it is the worst thing you can to for performance. i have seen some systems add 150lbs.... Wire, subs, amps, capacitors, all add weight....

personally i want the new Jpipe rev3 just for the added sound it might give me......

just a midnight thought

I'm glad someone finally posted up the science regarding lightened pullies. I've been arguing this very thing for years on this site and have even gotten into it with the owner of Unorthrodox racing who swears up and down that their pullies always see 8whp+ on the dyno in 4th gear. It's simply not possible for the very reasons Cross-Hair posted. As I told the owner of UR, the physics are against him. That's when he left the argument.

Is there power to be gained by reducing the pulley weight? Yes, but the power gain varies greatly across the gears. In the 1/4 mile, a car spends very very little time accelerating in 1st gear and even 2nd gear. This is where the major gains are with the pullies. A gain of 9whp and 6whp in 1st and 2nd across the span of around 6 seconds is going to have very little impact on acceleration. The car spends most of the time accelerating in 3rd and some of 4th and the gains are minimal.

Calculate the gains per gear spread out over time across a 1/4 mile run and you'll see that you're TL will be making a mere 2-3whp more than stock. Sorry, that not going to equate to any measureable drop in the ET or MPH improvement.

The argument of moment of inertia comes up as well. I've had a UR pulley on my VQ30 Maxima and it shed the same amount of weight as the one offered from the TL. That car went to the strip a lot and the pulley showed absolutely no improvement in the 1/4 mile with the pulley nor anything on the dyno. It made the car fractionally harder to launch consistently because of the reduced inertia (ie more prong to bog). I removed the pulley after 2 years use and over 40 1/4 mile passes. I ran my best ever AFTER removing the UR pulley. Go figure.

I guess so many gravitate mod because it's easy. Just like catbacks and intakes. And just like many of these mods, the advertized gains are often not there. I got suckered into believing the lightened pulley hype and learned my lesson after trying it at the strip, on the dyno, and understanding the physics behind it.

Is there power to be gained by reducing the pulley weight? Yes, but the power gain varies greatly across the gears. In the 1/4 mile, a car spends very very little time accelerating in 1st gear and even 2nd gear. This is where the major gains are with the pullies. A gain of 9whp and 6whp in 1st and 2nd across the span of around 6 seconds is going to have very little impact on acceleration. The car spends most of the time accelerating in 3rd and some of 4th and the gains are minimal.

Calculate the gains per gear spread out over time across a 1/4 mile run and you'll see that you're TL will be making a mere 2-3whp more than stock. Sorry, that not going to equate to any measureable drop in the ET or MPH improvement.

The argument of moment of inertia comes up as well. I've had a UR pulley on my VQ30 Maxima and it shed the same amount of weight as the one offered from the TL. That car went to the strip a lot and the pulley showed absolutely no improvement in the 1/4 mile with the pulley nor anything on the dyno. It made the car fractionally harder to launch consistently because of the reduced inertia (ie more prong to bog). I removed the pulley after 2 years use and over 40 1/4 mile passes. I ran my best ever AFTER removing the UR pulley. Go figure.

I guess so many gravitate mod because it's easy. Just like catbacks and intakes. And just like many of these mods, the advertized gains are often not there. I got suckered into believing the lightened pulley hype and learned my lesson after trying it at the strip, on the dyno, and understanding the physics behind it.

#37

So I am an ME and agree with all the math and Physics..... what no one has mention here is that We have a massive power plant that has to move a 3500lb car down the strip. one of the easiest mod anyone can do is remove weight from the car. It is by far the cheapest mod you can do. So in turn reducing the weight of the pulley actually helps in overall weight of the car but cost $$$..... this is my two cents.

Example: all those people who add sound systems to there car all it does is adds weight. sure they sound good but it is the worst thing you can to for performance. i have seen some systems add 150lbs.... Wire, subs, amps, capacitors, all add weight....

personally i want the new Jpipe rev3 just for the added sound it might give me......

just a midnight thought

Example: all those people who add sound systems to there car all it does is adds weight. sure they sound good but it is the worst thing you can to for performance. i have seen some systems add 150lbs.... Wire, subs, amps, capacitors, all add weight....

personally i want the new Jpipe rev3 just for the added sound it might give me......

just a midnight thought

#38

Yes! I removed about 20-25lbs off of my flywheel (torque convertor) and it went from a very slow revving engine to sounding almost like an indy car. A lightened flywheel *should* make a larger difference lb for lb since a lot of the weight is out at a much larger OD.

#39

#40

Does anyone have a technical drawing of CP? if i can get them I could make them cheaper than UR just need exact dimensions

just need exact dimensions I have a CNC and could make one as long as I have the right dimensions

I have a CNC and could make one as long as I have the right dimensions

just need exact dimensions

just need exact dimensions I have a CNC and could make one as long as I have the right dimensions

I have a CNC and could make one as long as I have the right dimensions

I just got the answer I needed, definitely picking one up before I do my timing belt

I just got the answer I needed, definitely picking one up before I do my timing belt  Two geniuses in here debating this. Doesn't an underdrive pulley start causing electrical problems over time?

Two geniuses in here debating this. Doesn't an underdrive pulley start causing electrical problems over time?