Axle Nut, What the Hell??

#1

Three Wheelin'

Thread Starter

Axle Nut, What the Hell??

Ok, I am changing my lower ball joints because I have some free time from work.

But for the hell of me, I can't remove the axle nut. I have tried everything besides heating it. I have a breaker bar with a 3 foot long pipe attached to it and it still wont budge.

I need some suggestions or am I missing something.

Also, I cant seem to fit anything into the axle nut cutout and bend the metal back out. This is the first time I have tried removing the axle nut since I have had this car.

Am I missing something???

But for the hell of me, I can't remove the axle nut. I have tried everything besides heating it. I have a breaker bar with a 3 foot long pipe attached to it and it still wont budge.

I need some suggestions or am I missing something.

Also, I cant seem to fit anything into the axle nut cutout and bend the metal back out. This is the first time I have tried removing the axle nut since I have had this car.

Am I missing something???

#3

Drifting

you will need a small chisel or a fat flathead screwdriver and a hammer. you have to tap the keeper tabs on the nut out of the keyway. then take an impact to the nut. it can be a pain in the ass sometimes.

#5

Three Wheelin'

Thread Starter

I finally got the axle nut off and what a hassle.

And yes, from what it looks like, you actually need access to the top of the lower ball joint and removing the axle nut is the only way you can do that.

Since you have to press the ball joint, you really have no choice but to do all of this. Whoever said this takes 15 minutes for each side is crazy.

Now I am having a problem getting the lower ball joint to break away and its starting to piss me off.

And yes, from what it looks like, you actually need access to the top of the lower ball joint and removing the axle nut is the only way you can do that.

Since you have to press the ball joint, you really have no choice but to do all of this. Whoever said this takes 15 minutes for each side is crazy.

Now I am having a problem getting the lower ball joint to break away and its starting to piss me off.

#6

Suzuka Master

iTrader: (4)

Originally Posted by pits200

I finally got the axle nut off and what a hassle.

And yes, from what it looks like, you actually need access to the top of the lower ball joint and removing the axle nut is the only way you can do that.

Since you have to press the ball joint, you really have no choice but to do all of this. Whoever said this takes 15 minutes for each side is crazy.

Now I am having a problem getting the lower ball joint to break away and its starting to piss me off.

And yes, from what it looks like, you actually need access to the top of the lower ball joint and removing the axle nut is the only way you can do that.

Since you have to press the ball joint, you really have no choice but to do all of this. Whoever said this takes 15 minutes for each side is crazy.

Now I am having a problem getting the lower ball joint to break away and its starting to piss me off.

#7

Three Wheelin'

Thread Starter

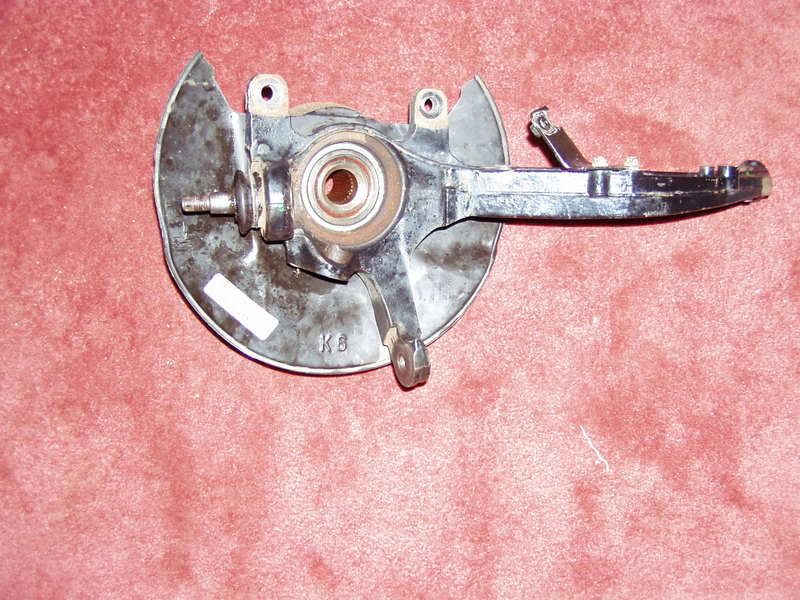

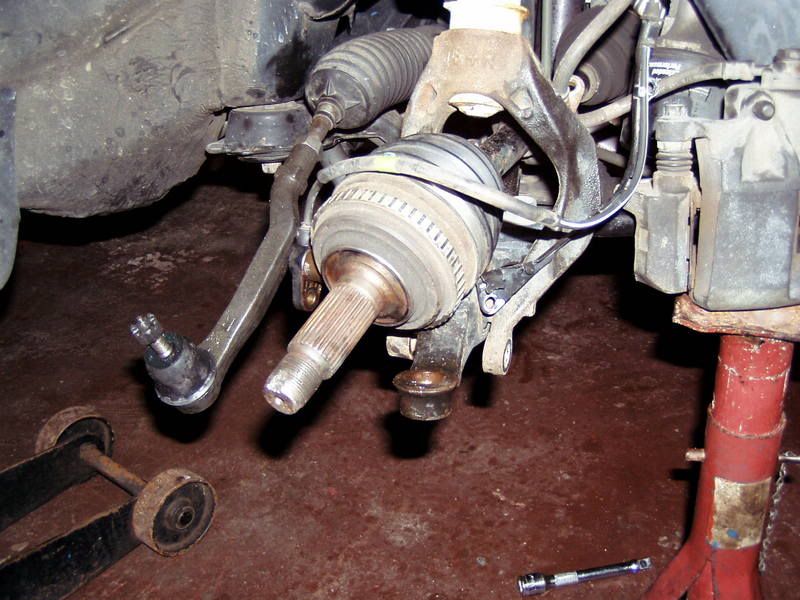

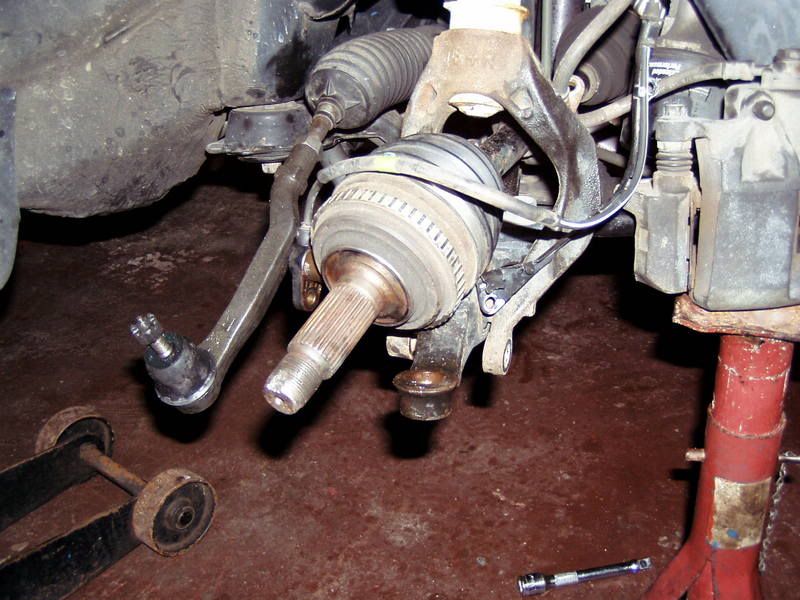

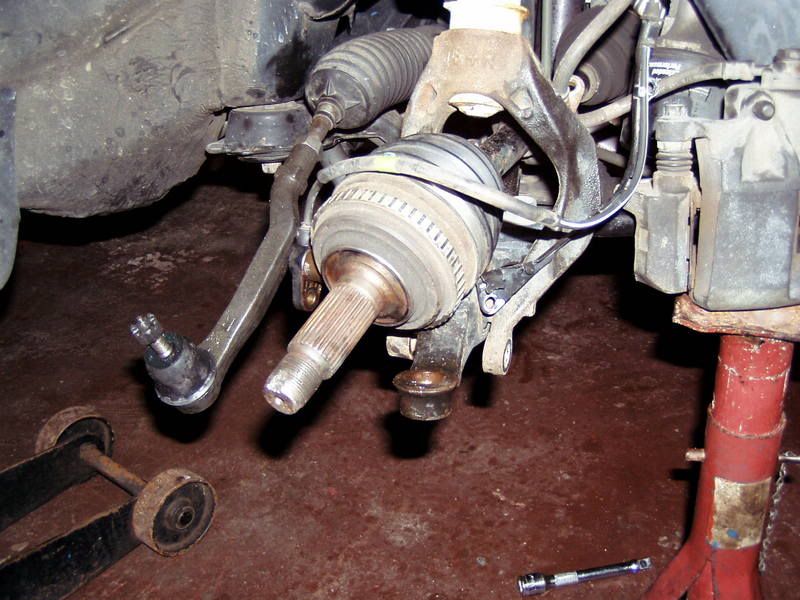

Here is a picture of everything that had to be taken apart.

1.) take off axle nut, i found it easier to put the tire back on and put the car back on the ground and then remove the center cap. This way you have the force of the tire on the car to remove the bolt.

2.) Take off caliper and undo brake line bolt.

3.) Take off strut bolt

4.) Take off tie rod end.

5.) Unscrew upper bolt joint nut.

6.) Undo lower ball joint nut.

7.) This should allow you to push the spindle down far and push the axle in so that they become disassembled.

8.) Work like never before and use a puller to get the lower ball joint to come loose.

9.) Once you get that loose, you need to lube up the ABS sensor and tap it loose from the inside with a flat head screwdriver. (You will see this wire running here and if you are like me, you will be afraid to break it.)

10.) Now you will have the spindle seperated from the car and have the ability to press out the lower ball joint.

1.) take off axle nut, i found it easier to put the tire back on and put the car back on the ground and then remove the center cap. This way you have the force of the tire on the car to remove the bolt.

2.) Take off caliper and undo brake line bolt.

3.) Take off strut bolt

4.) Take off tie rod end.

5.) Unscrew upper bolt joint nut.

6.) Undo lower ball joint nut.

7.) This should allow you to push the spindle down far and push the axle in so that they become disassembled.

8.) Work like never before and use a puller to get the lower ball joint to come loose.

9.) Once you get that loose, you need to lube up the ABS sensor and tap it loose from the inside with a flat head screwdriver. (You will see this wire running here and if you are like me, you will be afraid to break it.)

10.) Now you will have the spindle seperated from the car and have the ability to press out the lower ball joint.

Trending Topics

#11

Three Wheelin'

Thread Starter

Ha, you are probably right.. I didn't realize it was going to take so much work. If the lower ball joint didnt take so much time to break loose, it probably would have only taken me 20 minutes to get the spindle off the car

I would like to know what other people did who have changed their lower ball joint. Sometimes I am over conservative and take apart more things than necessary. I am going to be to busy to do the other side for awhile, I just wanted the experience of doing this on my CL.

PS. I just put on new MOOG Tie rod ends yesterday and that was probably one of the best upgrades to my CL in the recent months, especially since I have 115k miles on my ride. I also put on new sway bar end links for the front, these are moog also and are greaseable. But I didn't notice much of a difference from this.

I would like to know what other people did who have changed their lower ball joint. Sometimes I am over conservative and take apart more things than necessary. I am going to be to busy to do the other side for awhile, I just wanted the experience of doing this on my CL.

PS. I just put on new MOOG Tie rod ends yesterday and that was probably one of the best upgrades to my CL in the recent months, especially since I have 115k miles on my ride. I also put on new sway bar end links for the front, these are moog also and are greaseable. But I didn't notice much of a difference from this.

#12

Racer

wow you guys are really lucky to be able to get the ABS sensor out of the knuckle easily !

here in the province of Quebec where massive amounts of salt make our cars rust, a 1 year old car will need a new sensor because it'll break 100% of times you'll try to take it off.

about 3 years ago at work, i had to replace an axle on a 98 CL.... broke 2 breaker bars (½"drive), a no name and a snap-on (i bent and broke the snap-on ! lol)... we had to take the ¾"drive impact gun to take it off.

here in the province of Quebec where massive amounts of salt make our cars rust, a 1 year old car will need a new sensor because it'll break 100% of times you'll try to take it off.

about 3 years ago at work, i had to replace an axle on a 98 CL.... broke 2 breaker bars (½"drive), a no name and a snap-on (i bent and broke the snap-on ! lol)... we had to take the ¾"drive impact gun to take it off.

#13

Three Wheelin'

Thread Starter

You are exactly right, mine was rusted on there pretty good and it was so tight, i was starting to wonder if it was screwed on somewhere. I kept looking at it and thinking whether or not I was doing something wrong.

I just sprayed on some wd40 and let it sit for 5 minutes, then I just took the flathead screwdriver to the inside and worked my way around the ABS module.

I just sprayed on some wd40 and let it sit for 5 minutes, then I just took the flathead screwdriver to the inside and worked my way around the ABS module.

#14

Senior Moderator

Originally Posted by CleanCL

yea thats why im confused, if you follow the helms, it says to use a special tool to remove the lower balljoint without removing anything else. i bought the tool they said to use, so as soon as i get it i plan to attempt the install.

#15

Senior Moderator

Originally Posted by pits200

But for the hell of me, I can't remove the axle nut. I have tried everything besides heating it. I have a breaker bar with a 3 foot long pipe attached to it and it still wont budge.

#16

Racer

nice for the diy-ers, here we destroy them EVERYTIME (or when needing to take the knuckle off, we unplug the wire in the engine bay where there's a connector)

to get the ball joint easily out :

- remove cotterpin

- take off castle nut

- hit hard the lower control arm with a big hammer right where the balljoint's screw goes through (leave castle nut on for thread protection if only taking out knuckle keeping the same balljoint, but in this case here we are replacing the balljoint, so no need to protect it)

- lift knuckle by prying gently where the balljoint is

to get the ball joint easily out :

- remove cotterpin

- take off castle nut

- hit hard the lower control arm with a big hammer right where the balljoint's screw goes through (leave castle nut on for thread protection if only taking out knuckle keeping the same balljoint, but in this case here we are replacing the balljoint, so no need to protect it)

- lift knuckle by prying gently where the balljoint is

#18

Three Wheelin'

Thread Starter

Originally Posted by Type S Zero

nice for the diy-ers, here we destroy them EVERYTIME (or when needing to take the knuckle off, we unplug the wire in the engine bay where there's a connector)

to get the ball joint easily out :

- remove cotterpin

- take off castle nut

- hit hard the lower control arm with a big hammer right where the balljoint's screw goes through (leave castle nut on for thread protection if only taking out knuckle keeping the same balljoint, but in this case here we are replacing the balljoint, so no need to protect it)

- lift knuckle by prying gently where the balljoint is

to get the ball joint easily out :

- remove cotterpin

- take off castle nut

- hit hard the lower control arm with a big hammer right where the balljoint's screw goes through (leave castle nut on for thread protection if only taking out knuckle keeping the same balljoint, but in this case here we are replacing the balljoint, so no need to protect it)

- lift knuckle by prying gently where the balljoint is

LOL, hit it hard. Freakin A, I used a 20lb sledge to hit the castle nut and made sure it was upside down to to ensure not to bend the points and it still didnt budge. I ended up having to use a ball joint puller and then use a 17mm wrench to turn the puller and seperate the 2.

So a Mario Brothers hammer smash is ALWAYS my first option.

Also, there is a reason to protect the nut because if you bend the tips of the nut it is going to be a bitch to unthread after getting the ball joint off.

Lower Ball joints for me have always been a hassle because they take alot of the bouncing stress on a car and its never been as simple as a hammer smash for mine to come off. I hate using pullers because keeping them aligned and ensuring they don't fly off is annoying.

#19

Racer

Originally Posted by binTL

So how long does anything last on the underside of a car when they start rusting becoz of salt??..

how do u guys prevent or atleast slow this process?...

how do u guys prevent or atleast slow this process?...

for example, at my acura dealership, in the last 2 weeks, we did 3 lines jobs : repairing the lines from the middle of the car till the gas tank

- 2 rear brake lines

- 1 fuel supply line

- 1 fuel return line

- 1 gas vapors line

i did 2x 1.6EL ( the 1997 had gas tank replaced as well, the other was a 98) and another guy did a 98 integra. 9~12 hours each car

#20

Racer

Originally Posted by pits200

LOL, hit it hard. Freakin A, I used a 20lb sledge to hit the castle nut and made sure it was upside down to to ensure not to bend the points and it still didnt budge.

#21

Suzuka Master

iTrader: (4)

nice write up. what timing. i was just about to tackle this job myself, and also do the mood tie rod ends and sway bar end links. all of the moog stuff looks way better than stock, much beefier and stronger, can't wait to do all 3. i noticed the moog tie rod ends in your pictures. thanks for all the pictures, looks like i'll be bring it in someplace to do the lower balljoints, i dont have space to leave my car on jack stands while i get the ball joint pressed out.

#22

Three Wheelin'

Thread Starter

Originally Posted by CleanCL

nice write up. what timing. i was just about to tackle this job myself, and also do the mood tie rod ends and sway bar end links. all of the moog stuff looks way better than stock, much beefier and stronger, can't wait to do all 3. i noticed the moog tie rod ends in your pictures. thanks for all the pictures, looks like i'll be bring it in someplace to do the lower balljoints, i dont have space to leave my car on jack stands while i get the ball joint pressed out.

Before when I would wiggle the steering wheel back and forth from 10 to 2 and vice versa, I would feel a slight shimmy. I mean, it felt fine to probably the average person, but I am really picky about cars, so I decided to change some of the wear parts on the suspension.

CleanCl, wait till you take out the old tie rod and and wiggle the tip, it will be 10X looser than the moog tie rod end, the moog will be nice and lubed up and feel smoother.

As for the sway bar end links, its a joke how much thicker the moog ones are. My car feels flatter once I put these on, but that could also be a phantom from putting on the tie rod end. Its by far the best $100 bucks I spent, plus the 70 for an alignment.

#23

Blown is Best

Good job getting this done Pitts. I replaced the axles on the TL a few weeks ago and went through similar pain. I've got a Milwaukee electric impact gun that was able to break the axle bolts for me. I shattered the head on a Craftsman 1/2" breaker bar with a 2 foot extension on another car before so I had an idea what I was dealing with on the TL.

These removal instructions for the knuckle can be used as the first step in replacing wheel bearings or wheel studs.

I think this should go into the FAQ's as reference.

These removal instructions for the knuckle can be used as the first step in replacing wheel bearings or wheel studs.

I think this should go into the FAQ's as reference.

#24

Three Wheelin'

Thread Starter

I just got my shit pushed in by a local mechanic and I only had to pay him 10 bucks.

Well maybe I should rephrase that, I got my lower ball joint pressed in for $10 bucks. I was able to fiddle with everything yesterday and was able to get out the ball joint, but wasn't able to press in the new one.

I would say that for $150 bucks from the dealership with parts, that would not be a bad deal.

Well maybe I should rephrase that, I got my lower ball joint pressed in for $10 bucks. I was able to fiddle with everything yesterday and was able to get out the ball joint, but wasn't able to press in the new one.

I would say that for $150 bucks from the dealership with parts, that would not be a bad deal.

#26

Three Wheelin'

Thread Starter

I was checking my wheel bearings while I had it off and the hub didnt seem to spin completely free.

Does anyone know how free the CL bearing spins? It didn't make any sounds, but it seemed a little tight.

In addition, the job is actually cake putting it together. It only took me 20 minutes to put the car back together .

Does anyone know how free the CL bearing spins? It didn't make any sounds, but it seemed a little tight.

In addition, the job is actually cake putting it together. It only took me 20 minutes to put the car back together .

#27

MP90 uninstalled

Pitts,

I know this thread is ancient! I have pulled off my knuckles and have the OEM ball joint replacements in hand. I found the Acura TSB about the lower ball joints and it says not to replace them if there is a B stamped on the ball in the knuckle. Both my new balls and original balls have B’s stamped in them. I am the original owner of this car and have never had the balls replaced so these are the original balls. My car is a 2003 CLS 6mt. Do you think there is any reason I cant replace them anyway? Jim

I know this thread is ancient! I have pulled off my knuckles and have the OEM ball joint replacements in hand. I found the Acura TSB about the lower ball joints and it says not to replace them if there is a B stamped on the ball in the knuckle. Both my new balls and original balls have B’s stamped in them. I am the original owner of this car and have never had the balls replaced so these are the original balls. My car is a 2003 CLS 6mt. Do you think there is any reason I cant replace them anyway? Jim

#29

Three Wheelin'

Thread Starter

Pitts,

I know this thread is ancient! I have pulled off my knuckles and have the OEM ball joint replacements in hand. I found the Acura TSB about the lower ball joints and it says not to replace them if there is a B stamped on the ball in the knuckle. Both my new balls and original balls have B’s stamped in them. I am the original owner of this car and have never had the balls replaced so these are the original balls. My car is a 2003 CLS 6mt. Do you think there is any reason I cant replace them anyway? Jim

I know this thread is ancient! I have pulled off my knuckles and have the OEM ball joint replacements in hand. I found the Acura TSB about the lower ball joints and it says not to replace them if there is a B stamped on the ball in the knuckle. Both my new balls and original balls have B’s stamped in them. I am the original owner of this car and have never had the balls replaced so these are the original balls. My car is a 2003 CLS 6mt. Do you think there is any reason I cant replace them anyway? Jim

Hmm, I don't see any reason why they can't be replaced and what the difference is that they have a "B" stamped on them.

But my car is an 01 auto so there might be some kind of difference that I'm unaware of. I was trying to look at some of the pictures but I don't see any "B" listed anywhere on the ball joints I replaced.

I know its a PITA to wait but possibly you could call a dealership tomorrow to see what the whole "B" situation is.

But in my opinion, I would still replace them, maybe the TSB was just stating that the ones with the "B" are a second version and are not effected.

But honestly, I have no idea and if it were me, I would probably still replace them if the new ball joints you had looked identical in shape and size. If a machine shop can press them in, than more then likely everything is fine.

Sorry I can't give a more exact answer.

#30

MP90 uninstalled

Thanks,

I have the C Press tool with the Honda adapter parts but they wont fit over the ball joint, rediculous. Im going ot pepboys to see what they can do.

I have the C Press tool with the Honda adapter parts but they wont fit over the ball joint, rediculous. Im going ot pepboys to see what they can do.

#32

Three Wheelin'

Thread Starter

Sorry man I don't. I wasn't planning on even taking any pictures but when I was waiting to get the joint pressed in, I decided to grab my camera and take some pictures.

What do you need to see the other side for?

What do you need to see the other side for?

#33

Three Wheelin'

Thread Starter

Good luck with pep boys. I have an awesome machine shop around my area and they had no issues at all.

#34

LFG RANGERS!!!!!!!!!!!

iTrader: (6)

My mechanic apparently put my suspension back together wrong. I posted a thread asking for a picture of the correct orientation of the right suspension.

https://acurazine.com/forums/2g-cl-tires-wheels-suspension-54/need-picture-passenger-side-suspenson-2gen-cl-please-710289/

I wanted to show him a picture of a car whose suspension was correctly installed and not destroying boots.

I saved what you posted as it has the bolt in back.

The way to tell I learned is where is the pinch bolt.

It belongs on the back, he put it together backwards.

Thanks

https://acurazine.com/forums/2g-cl-tires-wheels-suspension-54/need-picture-passenger-side-suspenson-2gen-cl-please-710289/

I wanted to show him a picture of a car whose suspension was correctly installed and not destroying boots.

I saved what you posted as it has the bolt in back.

The way to tell I learned is where is the pinch bolt.

It belongs on the back, he put it together backwards.

Thanks

#35

Three Wheelin'

Thread Starter

HAHA, sorry to be laughing at your pain, but he definitely put your fork on the wrong way and the bend is leaning in towards the boot and this is why they are getting destroyed.

The shock is suppose to have a thin piece of metal on one section and this is suppose to line up with the cutout on the fork and once these are lined up, slide the shock into the fork , thats when the bolt is suppose to be tightened.

Also, what he might have done is not aligned the hat of the shock properly and the 3 bolts on the hat didn't match up with the openings right so this was mistake one and probably led to all the other issues.

Good luck man. Ive taken apart my suspension so many times, just ask if you have anymore questions. I'll try my best to help.

The shock is suppose to have a thin piece of metal on one section and this is suppose to line up with the cutout on the fork and once these are lined up, slide the shock into the fork , thats when the bolt is suppose to be tightened.

Also, what he might have done is not aligned the hat of the shock properly and the 3 bolts on the hat didn't match up with the openings right so this was mistake one and probably led to all the other issues.

Good luck man. Ive taken apart my suspension so many times, just ask if you have anymore questions. I'll try my best to help.

#36

LFG RANGERS!!!!!!!!!!!

iTrader: (6)

I'd be laughing if it were not my problem.

I paid him to replace the boots & bought the boots, I bought another boot yesterday so I would not have to wait for parts when I go back.

I thought he must have messed something up but did not want to be a jerk & blame him so I just asked for a break on the labor he gave me .3 hours off the 1.8 his program told him to charge.

In his defense he is a Toyota mechanic, he has been working on my Landcruiser for years, he rebuilt the motor in 2006. I am sure he will do the right thing.

My plan is that he refund the money I paid Friday for the labor and that he fix the suspension and replace the boot.

I left a message yesterday and am hoping they open tomorrow but I doubt they will, if I don't hear from them tomorrow I plan to be there at 7am Tuesday when they open.

I paid him to replace the boots & bought the boots, I bought another boot yesterday so I would not have to wait for parts when I go back.

I thought he must have messed something up but did not want to be a jerk & blame him so I just asked for a break on the labor he gave me .3 hours off the 1.8 his program told him to charge.

In his defense he is a Toyota mechanic, he has been working on my Landcruiser for years, he rebuilt the motor in 2006. I am sure he will do the right thing.

My plan is that he refund the money I paid Friday for the labor and that he fix the suspension and replace the boot.

I left a message yesterday and am hoping they open tomorrow but I doubt they will, if I don't hear from them tomorrow I plan to be there at 7am Tuesday when they open.

#37

Three Wheelin'

Thread Starter

Just make sure to keep that boot clean if there are any tears in it, you don't want to get any dirt into the axle but thats obvious.

I understand he is a Toyota mechanic, but suspension work is somewhat universal on these foreign cars.

No offense against him because it sounds like you have a good relationship with him. But he did take the car apart and all the had to do was make sure to put it back together the same way. If he was at all unsure, he should have checked the other side or did some research, or took some notes while taking it apart.

Hopefully he refunds the majority of your money because this was an issue that never should have happened and he is 100% at fault.

I understand he is a Toyota mechanic, but suspension work is somewhat universal on these foreign cars.

No offense against him because it sounds like you have a good relationship with him. But he did take the car apart and all the had to do was make sure to put it back together the same way. If he was at all unsure, he should have checked the other side or did some research, or took some notes while taking it apart.

Hopefully he refunds the majority of your money because this was an issue that never should have happened and he is 100% at fault.

Thread

Thread Starter

Forum

Replies

Last Post

rp_guy

Member Cars for Sale

9

07-16-2017 07:33 AM

08_UA7_Gr33k

Member Cars for Sale

13

02-11-2016 02:17 PM