The official random J series picture thread

#2

Senior Moderator

Nice. Im still waiting for my crank bearings to come in. They are back ordered from acura

#4

Senior Moderator

I got my pistons the next day. crank took like 3. Bearings

They had the lowers but not the uppers (at least in the color yellow i needed)

They had the lowers but not the uppers (at least in the color yellow i needed)

#5

Senior Moderator

I see you have the bearings for the con rods

#6

Nope, those are the old ones left in from the original 3.7.

Btw, thanks for the help on the bearings. As it turns out, the guy at Acura had no clue (as you had predicted) what the hell he was talking about...and I only assumed I knew what I was talking about.

Back to the original intent if the thread, I'll keep some pictures going...

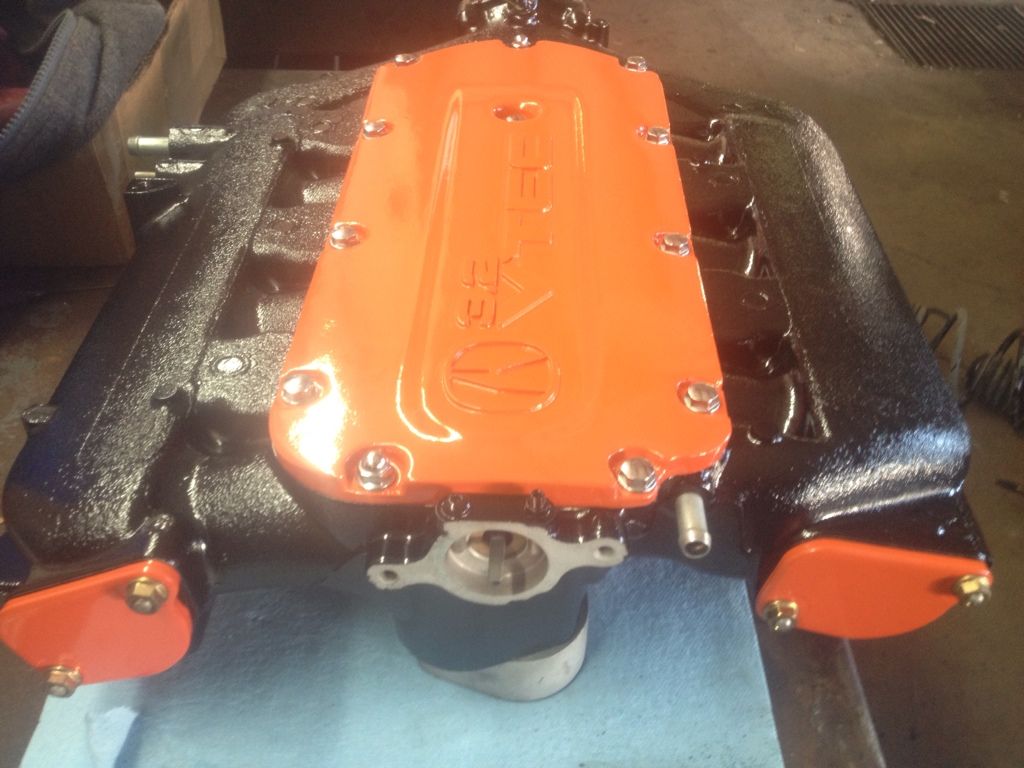

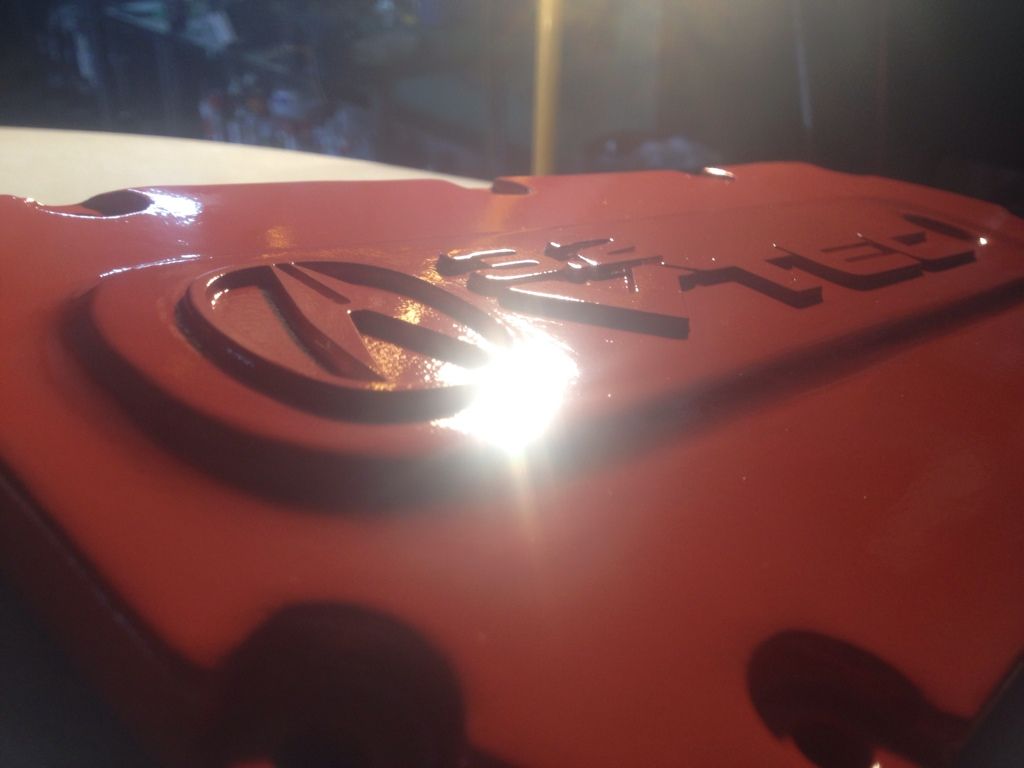

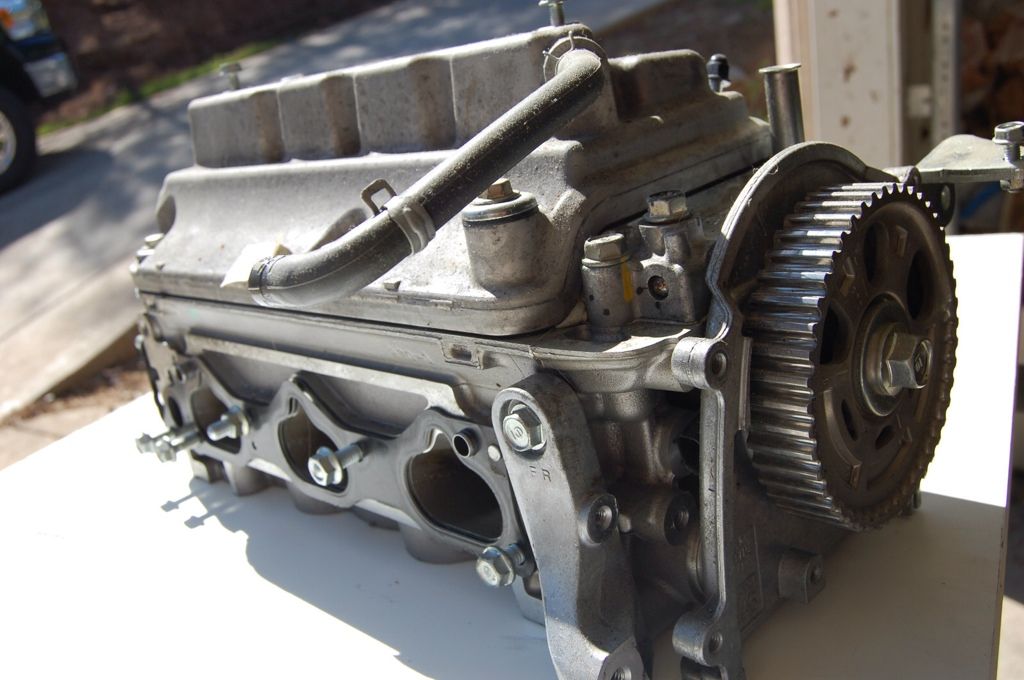

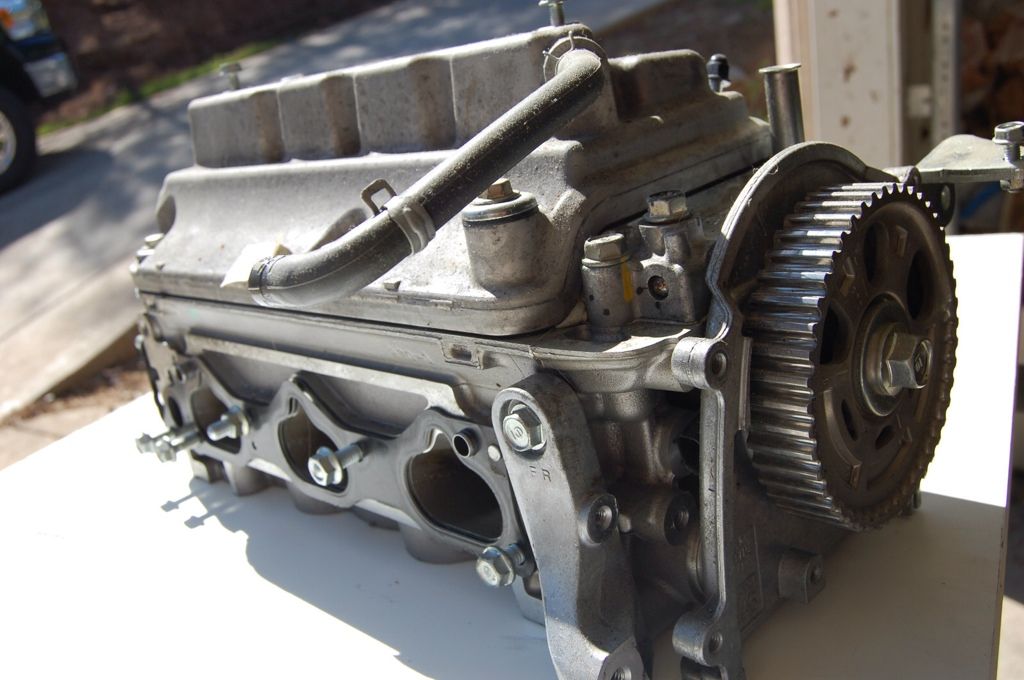

Here's my j32a2 block that's been bored to 90mm and has had dowels installed between the cylinders and the block. The powder coating was actually done before the machine work was because it was originally going to be a 3.5 build if anyone remembers.

Btw Fsttyms1, lets see them 3.7 build pictures!!!

Btw, thanks for the help on the bearings. As it turns out, the guy at Acura had no clue (as you had predicted) what the hell he was talking about...and I only assumed I knew what I was talking about.

Back to the original intent if the thread, I'll keep some pictures going...

Here's my j32a2 block that's been bored to 90mm and has had dowels installed between the cylinders and the block. The powder coating was actually done before the machine work was because it was originally going to be a 3.5 build if anyone remembers.

Btw Fsttyms1, lets see them 3.7 build pictures!!!

Trending Topics

#9

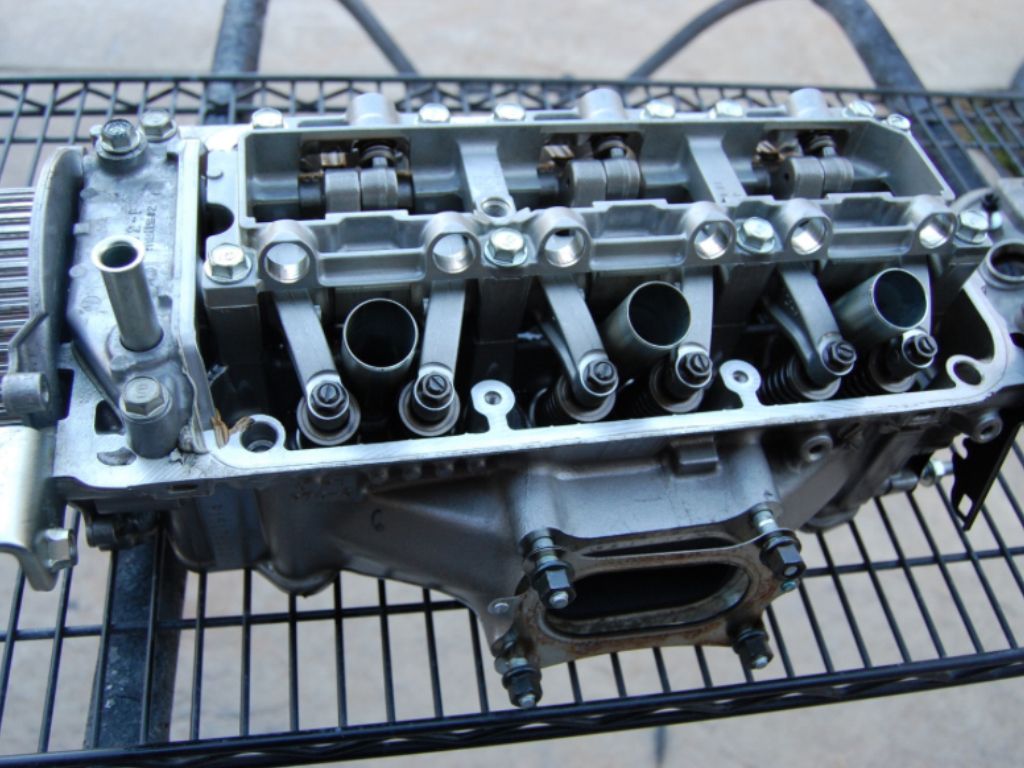

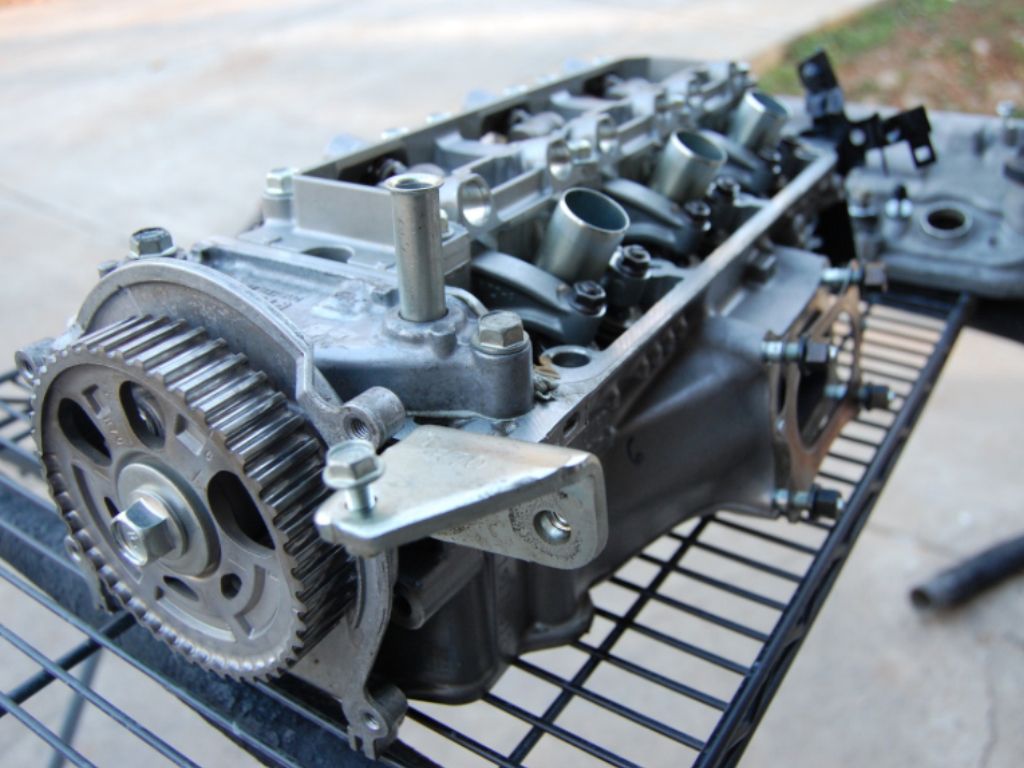

It's an optical illusion and they possess the same integrated cam caps as the traditional heads. The girdle is simply there to reinforce the rockers that were redesigned to work around the spark plug tubes with extreme angles to give them added strength. They went from a 5 lobe camshaft to a 4 lobe WHILE maintaining VTEC on the intake. Another thing about these cams, they were designed with weight savings in mind and therefore used splined lobes that are pressed onto the hollow camshaft. Here's the thing: this makes them unable to be reground for added lift.

As for compatibility, I'm very certain (not confirmed) that they work with 2nd gen j motors such as the j32a3 or j35a8 as they share the same water port holes and oil drain holes with this head. And as for valve sizes, they have the same 36mm valves as does the j32a2 heads. HOWEVER, Acura says the redesigned intake ports account for 15hp alone. That being said, these would (if combustion chambers were matched in size) be an excellent addition to ones 3.5 2nd gen j series build! And regrindable cams could simply be installed if larger cams are desired.

#10

Senior Moderator

I was thinking, since we cant really change the cam size, is there any reason we cant get larger rollers for the rockers? That would change the lift/duration. Then a cam could be cut/ground smaller if needed and change the lobe for different lift/duration giving us many more options  Might be something to look into

Might be something to look into

Might be something to look into

Might be something to look into

#11

I was thinking, since we cant really change the cam size, is there any reason we cant get larger rollers for the rockers? That would change the lift/duration. Then a cam could be cut/ground smaller if needed and change the lobe for different lift/duration giving us many more options  Might be something to look into

Might be something to look into

Might be something to look into

Might be something to look into

#12

Senior Moderator

Rockers only relay movement from its base point (camshaft) and cannot be made to increase lift UNLESS its by adding length which is practically impossible on ours heads unlike a small block V8 allows this by the movement in the pushrods. But, I have to applaud a mans attempt at trying.

Changing the rocker arm can not change the cam lobe.

Changing the rocker arm does change what happens at the valve. It changes because the valve reaches the effective duration sooner on the opening, higher, and later on the closing.

Last edited by fsttyms1; 04-08-2013 at 08:21 AM.

#13

Sure they can, yes you arent physically changing the cams duration spec, and yes they relay the movement, But If the roller wheel on it is larger (hence changing the rocker ratio) and the cam profile is the same/stock it will in effect open the valve sooner, more and keep it open longer. The cam "might" have to be reground to ensure that the valves would close all the way due to the increased normal height, and stiffer springs should probably be used to handle the increased lift. I have installed rockers(1.7+)/push rods on V8s that have required me to change cams because the lift/duration specs were off because of them.

Changing the rocker arm can not change the cam lobe.

Changing the rocker arm does change what happens at the valve. It changes because the valve reaches the effective duration sooner on the opening, higher, and later on the closing.

Changing the rocker arm can not change the cam lobe.

Changing the rocker arm does change what happens at the valve. It changes because the valve reaches the effective duration sooner on the opening, higher, and later on the closing.

Why not bore out 3 of the 4 cam bearing journals, use oversized cam bearings and then machine down the tops of the valve guides to gain 2-4mm of lift? Ive wanted to that for a while now and just need a reputable local machinist to line bore it and then make the bearings OR bearing spacers. That would be pretty damn vlose as to what other Honda/Acura's are getting in their performance cams.

#14

Senior Moderator

Hmm, maybe Im just not understanding your idea here.

Why not bore out 3 of the 4 cam bearing journals, use oversized cam bearings and then machine down the tops of the valve guides to gain 2-4mm of lift? Ive wanted to that for a while now and just need a reputable local machinist to line bore it and then make the bearings OR bearing spacers. That would be pretty damn vlose as to what other Honda/Acura's are getting in their performance cams.

Why not bore out 3 of the 4 cam bearing journals, use oversized cam bearings and then machine down the tops of the valve guides to gain 2-4mm of lift? Ive wanted to that for a while now and just need a reputable local machinist to line bore it and then make the bearings OR bearing spacers. That would be pretty damn vlose as to what other Honda/Acura's are getting in their performance cams.

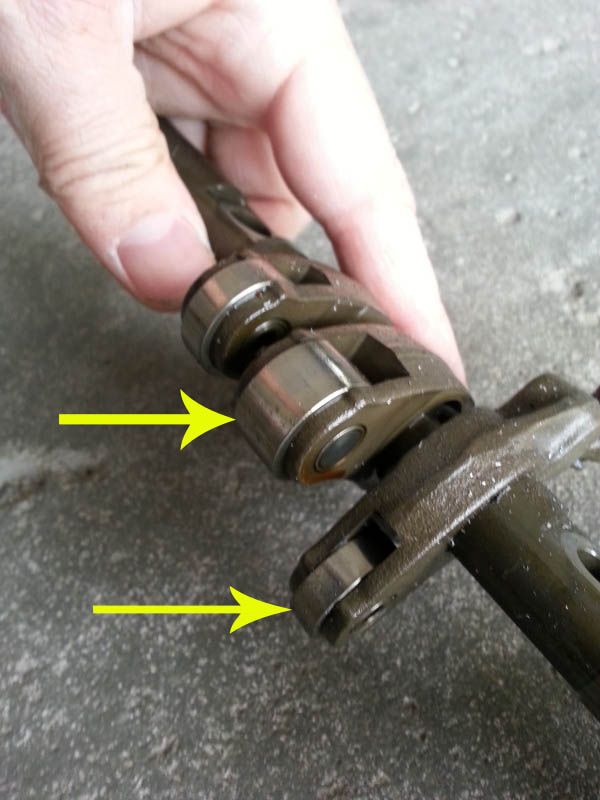

If one were to get custom wheels/bearings that roll on the cam (pointed to in yellow) or find ones that are larger it would change the rocker ratio.

#15

Senior Moderator

My J35a3 block bored and block guard

#16

Senior Moderator

Oh, i meant to ask you. How much did you have taken off your block. Im assuming by the looks of it and the dowels you decked it. (i had .006 taken off)

#17

Anyhow, the block looks nice with the guard in place my friend.

Also, I literally (while typing this) just received a phone call from Acura saying the last of my bearing just arrivedand theyre sending them over now. Have you received your yet?

#19

Senior Moderator

Well, TBH, there's a certain individual over at net that really jacked up the block upon resurfacing the deck and because of this I have absolutely no idea how far down it was taken total until I actually take some measurements. But Im afraid that it couldve been ruined and that REALLY pisses me off...especially after paying $3400 for essentially nothing.

Anyhow, the block looks nice with the guard in place my friend.

Also, I literally (while typing this) just received a phone call from Acura saying the last of my bearing just arrivedand theyre sending them over now. Have you received your yet?

Anyhow, the block looks nice with the guard in place my friend.

Also, I literally (while typing this) just received a phone call from Acura saying the last of my bearing just arrivedand theyre sending them over now. Have you received your yet?

Thanks. cant wait to get it assembled. My 3.5 bearings are in, i just havent gotten over there to see if they will work. 4 of the 3.7 lowers and 1 upper came though, so i have it to compare them to.

The following users liked this post:

KaotikPlaya (05-05-2013)

#20

Senior Moderator

Regional Coordinator

(Mid-Atlantic)

Regional Coordinator

(Mid-Atlantic)

iTrader: (6)

#21

That sucks. Hopefully its not too far. Hopefully if it is it could be made up with a slightly thicker MLS headgasket?

Thanks. cant wait to get it assembled. My 3.5 bearings are in, i just havent gotten over there to see if they will work. 4 of the 3.7 lowers and 1 upper came though, so i have it to compare them to.

Thanks. cant wait to get it assembled. My 3.5 bearings are in, i just havent gotten over there to see if they will work. 4 of the 3.7 lowers and 1 upper came though, so i have it to compare them to.

I got to thinking about the bearing thing you had explained. Im sure that all the bearings do match in regards to specs and all. Thats because all 2nd gen bottom ends are interchangeable. However, my thoughts were the material type being different...or maybe even a different size oil groove

than the other. I dont think either of the two would be an issue (well, atleast short term) but I wouldnt mix any of the bearings from one engine to the next. Not that I think you would or anything...just clarifying.

Whats the desired compression ratio on the build mind me asking? Also, are you aware that the TL 3.7 pistons have oil cooler grooves? That means that your block can be machined very easily into actually functioning for this feature along with about $30 in parts. Should help alot with service life as well as any sort of detonation issues that could occur by keeping the pistons cooler.

#22

J35 _ 5 Speed A/T

iTrader: (14)

As for compatibility, I'm very certain (not confirmed) that they work with 2nd gen j motors such as the j32a3 or j35a8 as they share the same water port holes and oil drain holes with this head. And as for valve sizes, they have the same 36mm valves as does the j32a2 heads. HOWEVER, Acura says the redesigned intake ports account for 15hp alone. That being said, these would (if combustion chambers were matched in size) be an excellent addition to ones 3.5 2nd gen j series build! And regrindable cams could simply be installed if larger cams are desired.

Members on V-6-P had discussed doing a top end swap onto their J30a4/a5......; specifically the heads from a 3.7

they were pretty sure they could do it, but don't think anyone has actually tried it yet.

from a 6th gen Accord point of view --- Our J30A1's along with Acura's J32A2, J35A3's and such had some and were interchangeable with parts from all those models......don't see why the DBW engines couldn't do the same in a lil' aspect to their generation.

getting some flowbench tests on stock vs ported would fill in some gaps.

Last edited by WHEEELMAN; 04-11-2013 at 08:31 PM.

#23

Members on V-6-P had discussed doing a top end swap onto their J30a4/a5......; specifically the heads from a 3.7

they were pretty sure they could do it, but don't think anyone has actually tried it yet.

from a 6th gen Accord point of view --- Our J30A1's along with Acura's J32A2, J35A3's and such had some and were interchangeable with parts from all those models......don't see why the DBW engines couldn't do the same in a lil' aspect to their generation.

getting some flowbench tests on stock vs ported would fill in some gaps.

they were pretty sure they could do it, but don't think anyone has actually tried it yet.

from a 6th gen Accord point of view --- Our J30A1's along with Acura's J32A2, J35A3's and such had some and were interchangeable with parts from all those models......don't see why the DBW engines couldn't do the same in a lil' aspect to their generation.

getting some flowbench tests on stock vs ported would fill in some gaps.

The j35a8 do not have the new port design as the j37 heads although they were .5mm larger vertically and horizontally than the previous j32a3 heads.

As I said before, our biggest obstruction with these motors aren't with the heads, its the cams. I'm certain if we could manage to fit large cams (even more so than current aftermarket ones) in these heads, we could push 400hp base pretty easily. And I'm also certain it's a viable possibility if someone would put some focus on a logical idea and finding a quality machine shop to perform the work. So much potential to unlock with these motors, we haven't even began...

#24

Senior Moderator

Yeah, seen that thread that you're talking about. I believe they were 'planning' on doing the rockers for the addition of exhaust VTEC. He successfully installed j35a8 heads (which was already known to fit) and said he would would do the rockers but didn't feel like investing in the expensive parts was worth the possibility of fitment issues.

The j35a8 do not have the new port design as the j37 heads although they were .5mm larger vertically and horizontally than the previous j32a3 heads.

As I said before, our biggest obstruction with these motors aren't with the heads, its the cams. I'm certain if we could manage to fit large cams (even more so than current aftermarket ones) in these heads, we could push 400hp base pretty easily. And I'm also certain it's a viable possibility if someone would put some focus on a logical idea and finding a quality machine shop to perform the work. So much potential to unlock with these motors, we haven't even began...

The j35a8 do not have the new port design as the j37 heads although they were .5mm larger vertically and horizontally than the previous j32a3 heads.

As I said before, our biggest obstruction with these motors aren't with the heads, its the cams. I'm certain if we could manage to fit large cams (even more so than current aftermarket ones) in these heads, we could push 400hp base pretty easily. And I'm also certain it's a viable possibility if someone would put some focus on a logical idea and finding a quality machine shop to perform the work. So much potential to unlock with these motors, we haven't even began...

Last edited by fsttyms1; 04-12-2013 at 07:39 AM.

#25

Senior Moderator

The head gasket work work as long as the deck wasnt brought below zero clearance with the pistons...otherwise the block is for sure trashed. Hopefully its just a matter of dealing with increased compression instead.

I got to thinking about the bearing thing you had explained. Im sure that all the bearings do match in regards to specs and all. Thats because all 2nd gen bottom ends are interchangeable. However, my thoughts were the material type being different...or maybe even a different size oil groove

than the other. I dont think either of the two would be an issue (well, atleast short term) but I wouldnt mix any of the bearings from one engine to the next. Not that I think you would or anything...just clarifying.

Whats the desired compression ratio on the build mind me asking? Also, are you aware that the TL 3.7 pistons have oil cooler grooves? That means that your block can be machined very easily into actually functioning for this feature along with about $30 in parts. Should help alot with service life as well as any sort of detonation issues that could occur by keeping the pistons cooler.

I got to thinking about the bearing thing you had explained. Im sure that all the bearings do match in regards to specs and all. Thats because all 2nd gen bottom ends are interchangeable. However, my thoughts were the material type being different...or maybe even a different size oil groove

than the other. I dont think either of the two would be an issue (well, atleast short term) but I wouldnt mix any of the bearings from one engine to the next. Not that I think you would or anything...just clarifying.

Whats the desired compression ratio on the build mind me asking? Also, are you aware that the TL 3.7 pistons have oil cooler grooves? That means that your block can be machined very easily into actually functioning for this feature along with about $30 in parts. Should help alot with service life as well as any sort of detonation issues that could occur by keeping the pistons cooler.

Compression id like to be anywhere from 11-12:1, ideally id like 12:1 once i can get a way to tune it. I see no reason with a tune we cant safely run 12:1

I knew they had them, i just havent seen the J37 block to see how they were machined or what needs to be machined to work on the J35 block.

#27

Senior Moderator

Its not going to change the cams actual duration, but It would/should begin opening the valve sooner, and it would close it later due to its larger dia. (it does on larger ratio roller rockers for ohv engines)

#28

Bonki' Ehrite!

iTrader: (2)

Also keep in mind your piston to valve clearance with added lift of larger rollers.

#29

im going to compare the 2 to see what the difference is. Im still waiting for the other 3 bearings to come

Compression id like to be anywhere from 11-12:1, ideally id like 12:1 once i can get a way to tune it. I see no reason with a tune we cant safely run 12:1

I knew they had them, i just havent seen the J37 block to see how they were machined or what needs to be machined to work on the J35 block.

Compression id like to be anywhere from 11-12:1, ideally id like 12:1 once i can get a way to tune it. I see no reason with a tune we cant safely run 12:1

I knew they had them, i just havent seen the J37 block to see how they were machined or what needs to be machined to work on the J35 block.

The oil sprayers are nothing more than small capillaries drilled into the block tapping into pressurized oil galleries which is then threaded for a nozzle and banjo bolt that is curved upwards to spray beneath the piston. Here's a few shots of one on a k-series:

And another

#30

2012 Acura TL 3.7 forged aluminum pistons:

First shot is actually of the oil sprayer relief seen at the one o'clock position...

And of course, full floating pin bore. Not too mention flutter control orifices under the oil ring for high rev protection...

It's really hard to determine what's going on here but if you look at the color differences between the skirt (bright silver), the ring lands (dull gray) and then the tops (bright silver) you can see obvious color differences. Not sure what's going on but looking up close it appears that they two different materials and not just different machining methods. Anyone know?

First shot is actually of the oil sprayer relief seen at the one o'clock position...

And of course, full floating pin bore. Not too mention flutter control orifices under the oil ring for high rev protection...

It's really hard to determine what's going on here but if you look at the color differences between the skirt (bright silver), the ring lands (dull gray) and then the tops (bright silver) you can see obvious color differences. Not sure what's going on but looking up close it appears that they two different materials and not just different machining methods. Anyone know?

#31

And then here's some differences between the j37 and j35a8 crankshafts.

J37 left and j35 right- You can see how much larger the bob weights are on the j37 opposed to the j35...

J37 weighing in at 48.2lbs (with crank trigger ring)

J35 weighing in at 44lbs even (bare crank)

I expected much more of a weight difference as I initially judged by the size of the bob weights on the j37 crank but was shocked to see only a 4lb gap between the two. I thought maybe the bob weight thickness was thinner on the j37 but they measured out to the same thicknesses.

J37 left and j35 right- You can see how much larger the bob weights are on the j37 opposed to the j35...

J37 weighing in at 48.2lbs (with crank trigger ring)

J35 weighing in at 44lbs even (bare crank)

I expected much more of a weight difference as I initially judged by the size of the bob weights on the j37 crank but was shocked to see only a 4lb gap between the two. I thought maybe the bob weight thickness was thinner on the j37 but they measured out to the same thicknesses.

#32

Senior Moderator

Correct, nothing on the cam would change just larger rollers on the RA. I am still in the air about the valve opening earlier because the rocker is there solely to transfer motion from cam to valve, the cam lobe is the same so I am mot sure if valve duation would change or not, Ive been thinking about it for a while now.

Also keep in mind your piston to valve clearance with added lift of larger rollers.

Also keep in mind your piston to valve clearance with added lift of larger rollers.

#33

Senior Moderator

And then here's some differences between the j37 and j35a8 crankshafts.

J37 left and j35 right- You can see how much larger the bob weights are on the j37 opposed to the j35...

J37 weighing in at 48.2lbs (with crank trigger ring)

J35 weighing in at 44lbs even (bare crank)

I expected much more of a weight difference as I initially judged by the size of the bob weights on the j37 crank but was shocked to see only a 4lb gap between the two. I thought maybe the bob weight thickness was thinner on the j37 but they measured out to the same thicknesses.

J37 left and j35 right- You can see how much larger the bob weights are on the j37 opposed to the j35...

J37 weighing in at 48.2lbs (with crank trigger ring)

J35 weighing in at 44lbs even (bare crank)

I expected much more of a weight difference as I initially judged by the size of the bob weights on the j37 crank but was shocked to see only a 4lb gap between the two. I thought maybe the bob weight thickness was thinner on the j37 but they measured out to the same thicknesses.

I thought the same comparing the 2 i have at home. Id be willing to bet KMS could knife edge and lighten at least 5-7lbs off of the 3.7

#34

Bonki' Ehrite!

iTrader: (2)

The color difference is different coatings used. Often times coatings like DLC for slickness and durability, they are very hard and slick coatings.

Also, be careful on knife edging, it was a hot topic a few years back but after some research it was found that knife edged cranks led to excessive windage in the crankcase and actually a loss in horsepower due to it slinging excessive oil up onto cylinder walls. It was found that despite the extra weight a rounded edge on the weights is actually better as it cuts through the oil with no ill effects.

Now this is all based off high performance racing engines.

Also, be careful on knife edging, it was a hot topic a few years back but after some research it was found that knife edged cranks led to excessive windage in the crankcase and actually a loss in horsepower due to it slinging excessive oil up onto cylinder walls. It was found that despite the extra weight a rounded edge on the weights is actually better as it cuts through the oil with no ill effects.

Now this is all based off high performance racing engines.

#35

I won't mention any names but KMS has treated a reputable Azine member in a manner that I'd consider unprofessional to say the least. After spending 4-digit numbers with them on one transaction, they should be treating the customer as priority...not "ill finish whenever I can".

#36

So it was mentioned a few posts back that Acura's 3.7 (and all newer j35z series too) cylinder heads featured intake ports that were redesigned and added 15hp by themselves. Up until here recently, I'd never seen the newly redesigned ports. I was able to get a few pictures of them and wanted to share them with everybody.

But first, here's a shot of a j35a8 cheap which are the exact same design/shape as all prior j-series intake ports (if not all 93 and up Honda intake ports) with the only exception being 1/2mm wider and taller than both the most common j32a2 and j32a3 heads.

And here's the newly designed ports from the j37 (starting in 07 with the MDX) and as you can tell, they've got shorter and wider ports.

Here's a the information about the heads/new port design taken directly from Acuranews.com:

"The MDX's new intake port design has an optimized shape that contributes seven horsepower (relative to the old design) to the MDX's 300 horsepower total. Intake valves in the new engine are 36mm in diameter (an increase of 1mm), yet weigh 13% less due to a reduction in material in the valve head. The exhaust valves measure 30mm in diameter, same as in the previous engine."

IMO, these may be an even better option for those who are looking for a better performance than other heads yet. Port volume and combustion chamber size of course still needs to be confirmed before that last sentence can be deemed accurate.

But first, here's a shot of a j35a8 cheap which are the exact same design/shape as all prior j-series intake ports (if not all 93 and up Honda intake ports) with the only exception being 1/2mm wider and taller than both the most common j32a2 and j32a3 heads.

And here's the newly designed ports from the j37 (starting in 07 with the MDX) and as you can tell, they've got shorter and wider ports.

Here's a the information about the heads/new port design taken directly from Acuranews.com:

"The MDX's new intake port design has an optimized shape that contributes seven horsepower (relative to the old design) to the MDX's 300 horsepower total. Intake valves in the new engine are 36mm in diameter (an increase of 1mm), yet weigh 13% less due to a reduction in material in the valve head. The exhaust valves measure 30mm in diameter, same as in the previous engine."

IMO, these may be an even better option for those who are looking for a better performance than other heads yet. Port volume and combustion chamber size of course still needs to be confirmed before that last sentence can be deemed accurate.

The following users liked this post:

Sonnick (04-15-2013)

#37

Senior Moderator

The color difference is different coatings used. Often times coatings like DLC for slickness and durability, they are very hard and slick coatings.

Also, be careful on knife edging, it was a hot topic a few years back but after some research it was found that knife edged cranks led to excessive windage in the crankcase and actually a loss in horsepower due to it slinging excessive oil up onto cylinder walls. It was found that despite the extra weight a rounded edge on the weights is actually better as it cuts through the oil with no ill effects.

Now this is all based off high performance racing engines.

Also, be careful on knife edging, it was a hot topic a few years back but after some research it was found that knife edged cranks led to excessive windage in the crankcase and actually a loss in horsepower due to it slinging excessive oil up onto cylinder walls. It was found that despite the extra weight a rounded edge on the weights is actually better as it cuts through the oil with no ill effects.

Now this is all based off high performance racing engines.

#38

Senior Moderator

I figure they widened them up to give them extra volume. Wouldnt make much sense to make them taller, especially with the height of the head, but going wider would definitely give them a good amount of increase. Good to see the difference.

#39

Senior Moderator

Never thought about them being coated. I suppose that could be it. I wonder if Acura uses both hypereutectic and forged materials to make up this piston? In Acuranews.com they list these as forged aluminum but you can clearly see casting marks beneath the underside. This could mean that only certain parts are forged...because some are clearly NOT. This could give them the anti-expanding benefits of the hypereutectic material for much tighter tolerances and the strength of being forged in critical areas...I dunno, just theorizing here. My initial thought was the pistons were comprised of different materials. However, the suggestion of it being a coating could also be likely.

I won't mention any names but KMS has treated a reputable Azine member in a manner that I'd consider unprofessional to say the least. After spending 4-digit numbers with them on one transaction, they should be treating the customer as priority...not "ill finish whenever I can".

I won't mention any names but KMS has treated a reputable Azine member in a manner that I'd consider unprofessional to say the least. After spending 4-digit numbers with them on one transaction, they should be treating the customer as priority...not "ill finish whenever I can".

#40

We have a windage tray, and really limits the amount of oil that actually touches the crank. Also the main point of it now is just weight reduction. Every pound taken off of rotating mass is huge for the amount of power that it frees up. We saw a 37hp at the wheels gain with 4lbs removed on a mustang engine we built, but the big thing was how quick it wanted to rev and how responsive it was.

As for the heads, I just realized the quote I posted from Acuranews.com reported 7hp from the redesigned intake ports. I read 14hp somewhere that was official but can't remember where. I suppose it could've been from the entire cylinder head. Now that I think about it, it was from another model listed on Acuranews.com....maybe the 2012 TL 3.7.